Technology

03

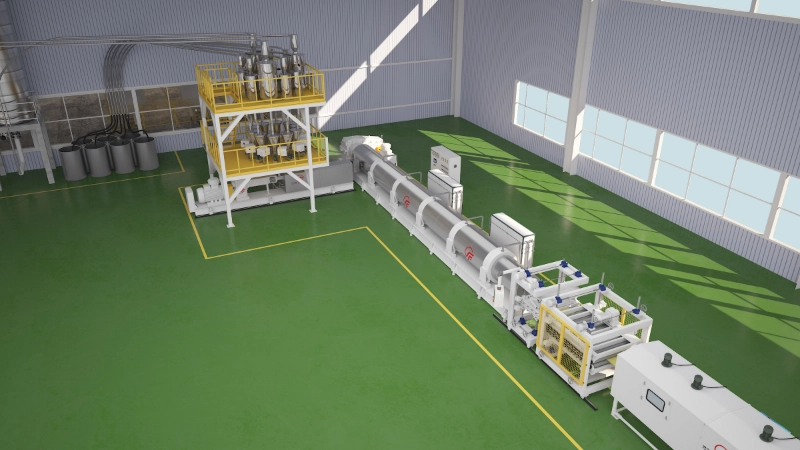

Jul . 2025As environmental regulations tighten and the global market seeks more sustainable construction solutions, the XPS foam board industry is entering a critical transition phase. Traditionally reliant on Freon as a blowing agent, manufacturers are now facing mounting pressure to adopt eco-friendly alternatives. Feininger, a pioneer in XPS foam board technology and manufacturing, has successfully embraced this shift through the development and implementation of a Carbon Dioxide Foam Extrusion Board Production Line — a revolutionary advancement for the industry.

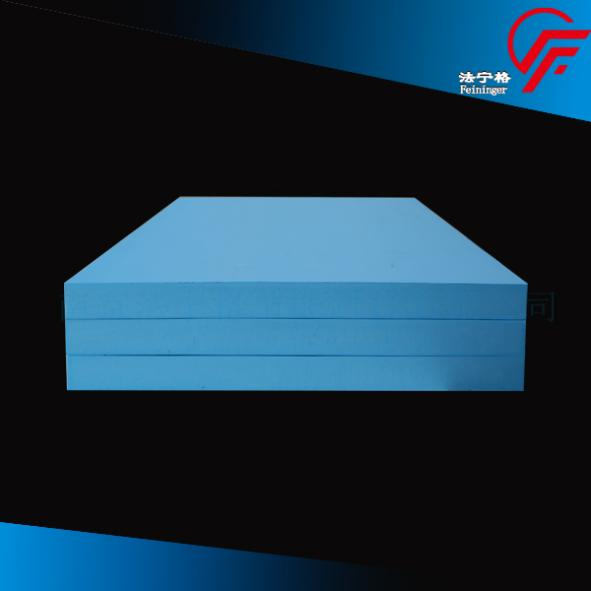

For decades, Freon-blown polystyrene foam boards were favored for their excellent insulation, compressive strength, low water absorption, and lightweight structure. These properties made them ideal for applications such as:

Building external wall insulation

Cold storage

Central air conditioning pipelines

Water conservancy and transportation infrastructure (e.g., highways, airport runways, rail subgrades)

However, under the Montreal Protocol, Freon (CFC-11 and related substances) is officially listed as an ozone-depleting agent. By 2026, its production and use will be fully banned worldwide. Additionally, the rising cost of Freon — over ¥20,000 per ton — poses a major burden on manufacturers.

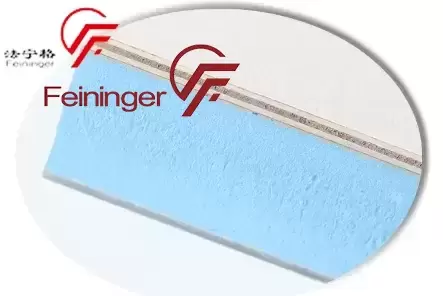

After years of R&D, Feininger has perfected a production line that replaces Freon with 100% carbon dioxide as the blowing agent, achieving cleaner production with lower costs and enhanced environmental compliance. The resulting CO₂-blown XPS boards deliver:

Foam thickness up to 100mm

Bulk density as low as 27kg/m³

Zero ozone depletion potential

Stable, high-performance insulation for modern construction demands

From an environmental standpoint, this innovation helps eliminate high-GWP (global warming potential) gases. From a cost perspective, CO₂ costs approximately ¥800 per ton, allowing a single line producing 150,000 square meters annually to save nearly ¥10 million in blowing agent costs.

Feininger's carbon dioxide extrusion line is engineered for precision, consistency, and energy efficiency. It includes advanced components such as:

CO₂ front constant-pressure pump

High-pressure supply and buffer tanks

Accelerant supply unit

Dual-stage static mixers

Twin extruding screws with cooling control

Intelligent mold head with HMI (human-machine interface)

The process begins with liquid CO₂ stored at low temperature and low pressure (around -20°C, 2MPa), which is boosted to a stable supercritical state for controlled injection. The high-precision mass flowmeter system ensures consistent mixing of CO₂ with PS plastic and foaming accelerators. The result is a homogeneously mixed melt, processed into lightweight, structurally sound XPS boards.

Feininger's system integrates several cutting-edge innovations:

Carbon Dioxide Modification Technology

Alcohols and alkyl phosphate esters are used as synergists to enhance compatibility and foam efficiency.

High-Pressure Mixing

At up to 20MPa, CO₂ and foaming agents undergo repeated mixing cycles to ensure perfect distribution in the polymer melt.

Supercritical Control

CO₂ is maintained in a supercritical state during injection, boosting solubility by up to 100 times compared to liquid/gas.

Static Melt Mixing

A dual-stage static mixer prevents gas escape during extrusion, ensuring stable foam structure and material homogeneity.

With more than 20 years of experience, Feininger is one of China's first and most respected manufacturers of XPS foam board extrusion lines. The company’s forward-thinking adoption of CO₂ foam technology positions it as a global leader in sustainable insulation manufacturing. Feininger not only supplies XPS boards worldwide, but also empowers other manufacturers with complete turnkey solutions for CO₂ extrusion lines.

The shift to carbon dioxide foaming is not just a compliance necessity — it’s a smart investment in the future of insulation manufacturing. Feininger’s carbon dioxide foam extrusion board production line delivers cost savings, environmental benefits, and technological superiority, making it the clear choice for progressive manufacturers in a changing world.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

01 Sep 2023

01 Sep 2023 Durability and Versatility of Wooden Layer Sandwich Boards

Welcome to the world of wooden layer sandwich boards! These innovative and versatile building materials have been gaining popularity for their durability, strength, and aesthetic appeal.

05 Jan 2024

05 Jan 2024 Benefits of Using EPP Beads Foam in Your Production Line

Welcome to our blog post on the benefits of using EPP Beads Foam in your production line! If you're looking for a cost-effective and durable solution for your business, then you've come to the right place.

01 Feb 2024

01 Feb 2024 XPS Foam Board: Understanding R-Value & Installation

Looking to insulate your home or complete a DIY project? Consider XPS foam board. This versatile material offers excellent thermal resistance and moisture protection, making it ideal for various applications.