Technology

14

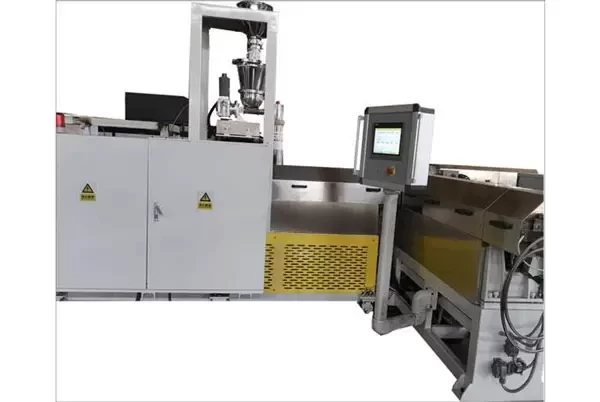

Nov . 2024PET foam extruder machines are essential in the production of lightweight, durable, and versatile materials used across various industries, including packaging, automotive, and construction. These machines are designed to ensure high performance, energy efficiency, and long-term reliability. Feininger’s PET sheet extrusion lines stand out by offering customizable modular designs that enhance productivity, reduce costs, and improve energy consumption.

However, like any high-tech industrial equipment, PET foam extruder machines can encounter issues from time to time. Understanding common problems and their solutions can help maintain optimal performance and prevent costly downtime. In this blog, we’ll explore some of the most common issues with PET foam extruder machines and provide solutions to help you troubleshoot and resolve them.

Problem: One of the most common problems with PET foam extruder machines is inconsistent foam quality. This can manifest as uneven foam density, irregular cell structure, or poor surface finish.

Cause: The issue often stems from improper temperature control, incorrect material formulation, or fluctuations in extrusion speed.

Solution:

Problem: Clogging is a frequent issue in PET foam extruder machines, which can disrupt production and even cause damage to the machine if left unresolved.

Cause: This can happen due to contamination in the raw materials, inadequate material pre-heating, or an improperly maintained extruder screw.

Solution:

Problem: While PET foam extruder machines are designed for energy efficiency, sometimes production lines may experience excessive energy consumption, leading to increased operational costs.

Cause: Inefficient machine settings, such as incorrect screw speeds, improper heating, or using outdated technology, can lead to higher energy demands.

Solution:

Problem: Overheating can cause melting issues, leading to poor material quality or even machine damage. It’s crucial to maintain the correct temperature profile to ensure smooth operation.

Cause: Overheating typically occurs due to improper cooling, inefficient temperature control systems, or a malfunction in the temperature sensors.

Solution:

Problem: PET foam products, such as sheets or boards, may suffer from dimensional inconsistency, such as warping or uneven thickness, which can affect product quality.

Cause: This issue can arise due to improper die settings, inconsistent cooling, or variations in the extrusion speed.

Solution:

Problem: Over time, key components of the PET foam extruder machine, such as the extruder screws, barrel liners, and die heads, may experience wear and tear.

Cause: Continuous use, improper material formulations, and lack of regular maintenance can accelerate wear on critical parts.

Solution:

Feininger’s PET sheet extrusion lines offer high performance, energy efficiency, and flexibility for companies in the plastics industry. However, like any advanced equipment, PET foam extruder machines may face challenges that could disrupt production. By understanding the common issues and knowing how to troubleshoot them, you can keep your production line running smoothly and efficiently.

Regular maintenance, optimal settings, and proper material handling are key to ensuring the longevity and reliability of your extruder machine. If you encounter persistent issues, don’t hesitate to consult with experts or upgrade your machinery to benefit from the latest technological advancements that improve productivity and reduce costs.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

19 Jun 2024

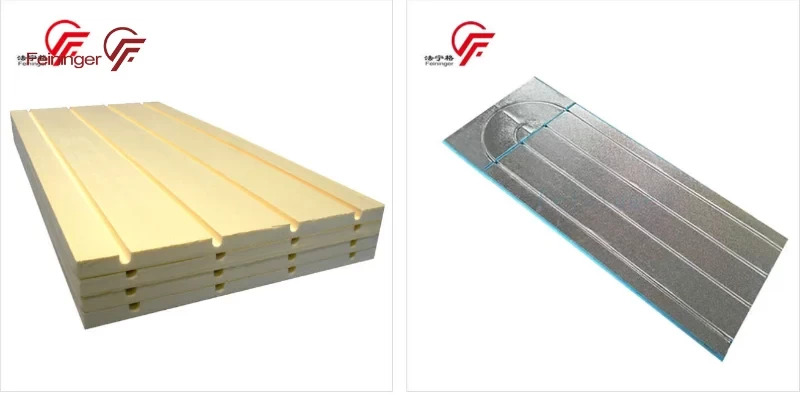

19 Jun 2024 Comparing Insulation Materials: Where Does XPS Foam Board with Aluminum Foil Stand?

In the world of insulation materials, the choices can seem endless. Among these, XPS (Extruded Polystyrene) foam board with aluminum foil has become a significant player, particularly in scenarios requiring robust thermal resistance and moisture protection.

06 Jan 2025

06 Jan 2025 EPS Floor Heating Sheets vs. Traditional Heating Systems: A Comprehensive Comparison

In modern construction and renovation projects, choosing the right heating system is crucial for energy efficiency, comfort, and long-term savings. Among the many options available, EPS floor heating sheets have emerged as a top contender, offering significant advantages over traditional heating methods.

29 Oct 2024

29 Oct 2024 How Feininger's Foam Sheet Laboratory Machine Enhances XPS Foam Research

In the rapidly evolving field of materials science, the need for advanced testing and research equipment is paramount. For researchers focused on extruded polystyrene (XPS) foam, the Foam Sheet Laboratory Machine from China Feininger stands out as an invaluable tool.