Technology

27

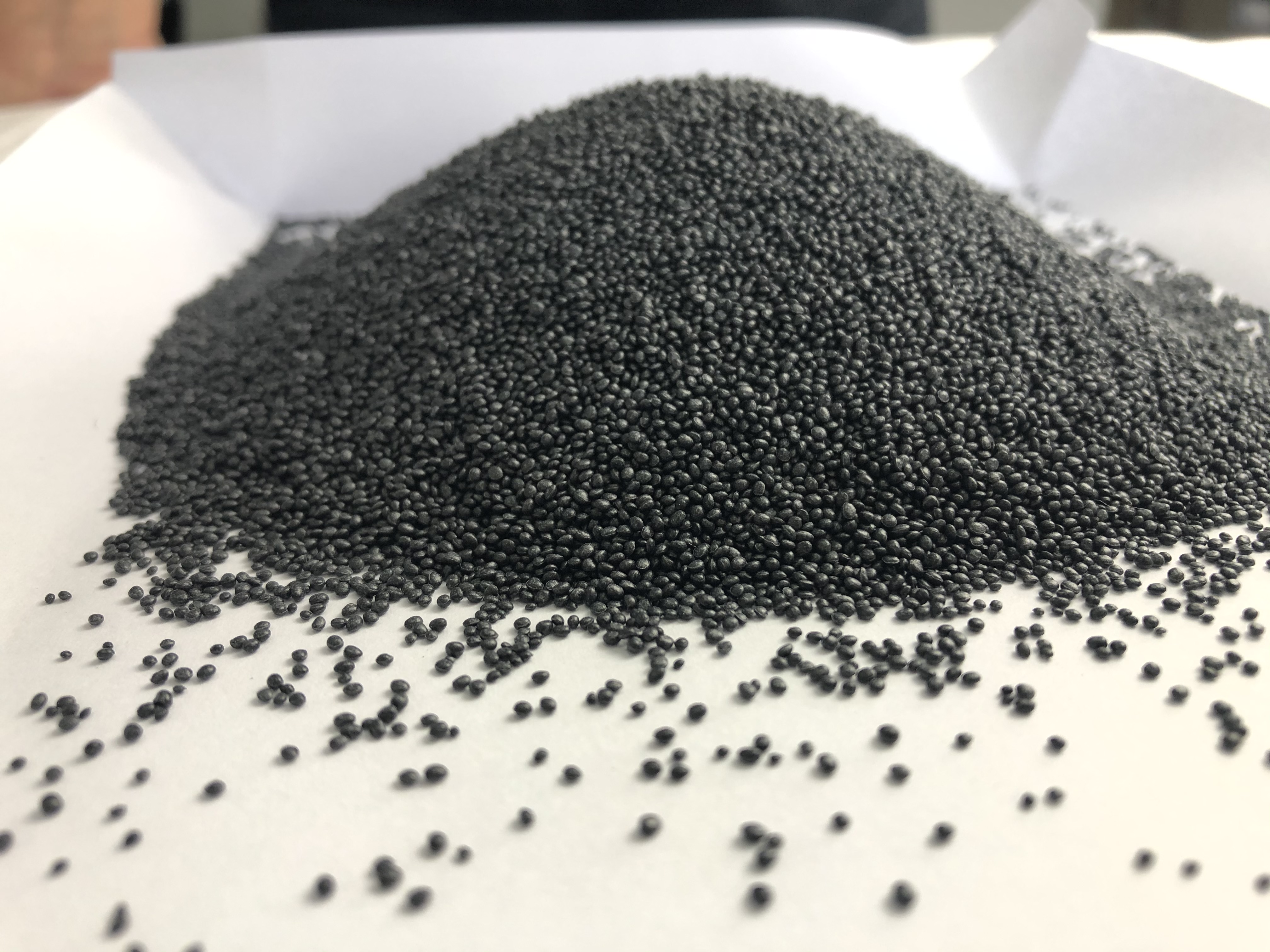

Aug . 2025The advantages of our company’s equipment for producing graphite EPS particles by extrusion are as follows:

1. Outstanding production efficiency and stability

The extrusion system is efficient and stable: a customized feeding system is used to feed materials. The screw and barrel are specially designed to achieve uniform extrusion pressure and good plasticizing effect. It can produce continuously and stably and avoid frequent shutdown adjustments.

2.High degree of automation

Equipped with an intelligent PLC control system, which can accurately set parameters such as feeding volume, temperature, speed, etc., reducing manual intervention and reducing production fluctuations caused by operating differences. The equipment operation failure rate is lower than the industry average.

3. Product quality

Good particle uniformity: During the extrusion process, graphite and EPS raw materials are fully mixed, the particle size deviation is small, and the subsequent molded products have high density consistency and reduce the scrap rate. The temperature control accuracy of the equipment reaches ±1℃, which avoids material degradation caused by local overheating and ensures the thermal insulation effect of the final product.

4. Energy consumption and cost advantages

The energy-saving design significantly reduces energy consumption by 10%-15% compared to traditional equipment, and long-term operation can effectively reduce production costs.

Long service life of wearing parts: key components (such as screws, molds, cutters) are made of wear-resistant materials, extending the service life by more than 30%, reducing the frequency of equipment maintenance and replacement, and reducing downtime losses.

5. Strong operation and adaptability

Easy to operate: Equipped with a human-computer interaction interface and intuitive parameter setting, novices can take up the job after simple training, reducing labor costs.

Wide adaptability: Production parameters can be flexibly adjusted to adapt to the production needs of granules of different specifications (0.8~2.0mm) and different formulas to meet diverse order requirements.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

14 Mar 2025

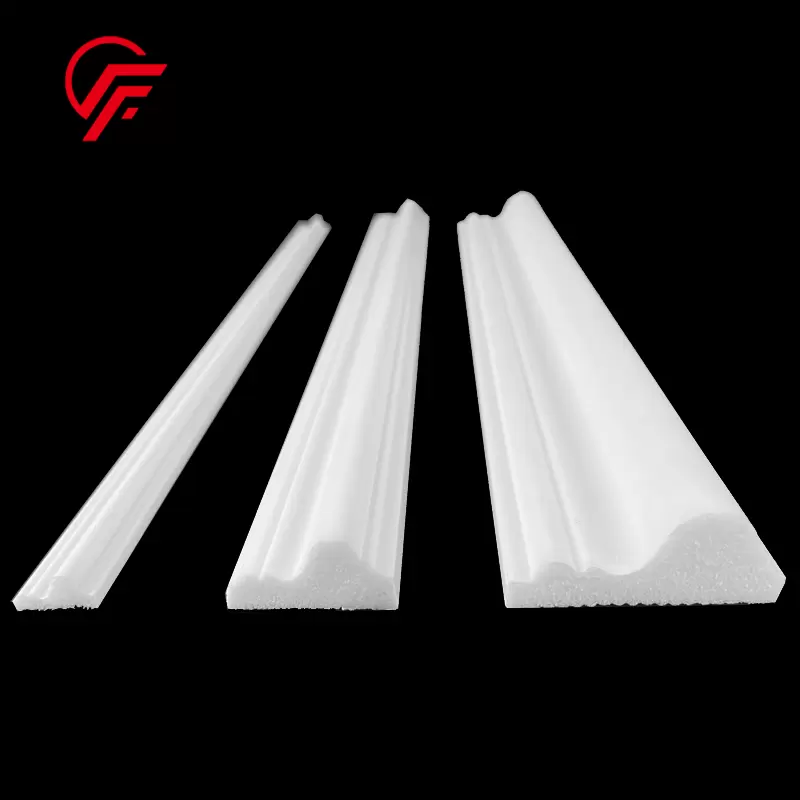

14 Mar 2025 Common Challenges in PS Skirting Production and How to Overcome Them

Polystyrene (PS) skirting boards have become a popular choice for interior and exterior decoration due to their lightweight nature, durability, and resistance to moisture. However, manufacturers often face several challenges in the production process, which can impact efficiency, quality, and sustainability.

19 Jul 2024

19 Jul 2024 Maximizing Efficiency with High-Performance Recycling Pelletizers

In today's fast-paced and environmentally conscious world, the need for efficient recycling solutions is more critical than ever. High-performance recycling pelletizers play a pivotal role in transforming plastic waste into reusable materials, contributing to both economic and environmental sustainability.

30 Oct 2023

30 Oct 2023 How to Choose PS Decorative Lines?

Welcome to our blog post on how to choose the perfect PS Decorative Lines for your home or office! If you're looking to enhance the aesthetics of your space and add a touch of elegance, then PS Decorative Lines are the ideal solution. These decorative lines not only serve as beautiful accents but also provide functionality and durability.