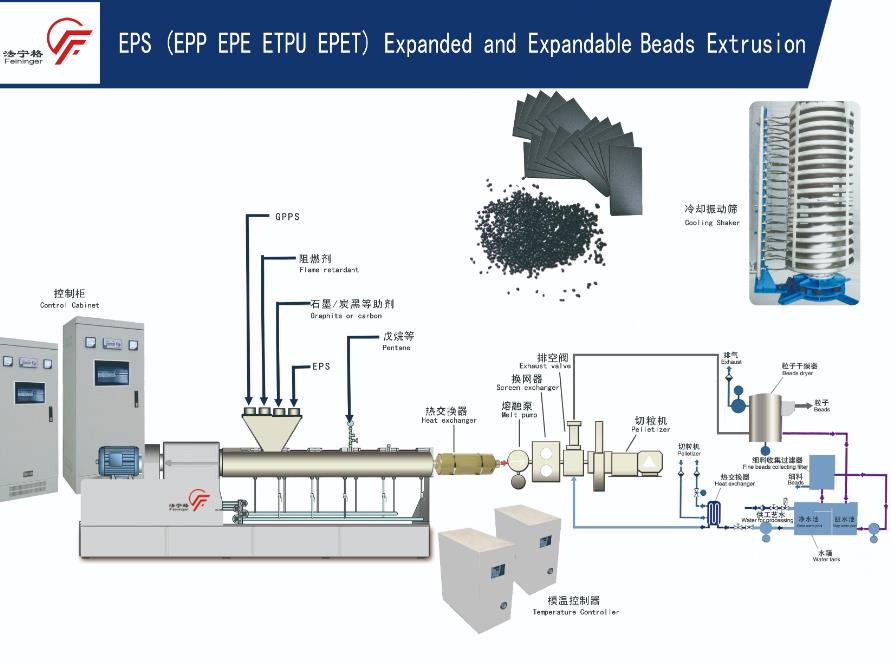

- New research and development of graphite EPS production line adopts the scientific design of extruder extrusion equipment.

- Feininger has rich production experience and parallel double screw design of advanced ideas, through the uniform temperature of the heat exchanger, the hole is not blocked, make the finished products with perfect quality.

Graphite EPS extrusion line can be completed from 200 kg/h to 2000 kg/h production capacity

Complete automatic production line

Turnkey Engineering Services (from consulting to operation)

Online remote analysis, diagnosis and technical support

Recommended Products

Inquiry

For the purchase, use, repair and maintenance of the product, you can contact us here

Solve parts, after-sales and service related problemsgo and have a look~

Send email to Feininger customer service centermarket@feininger.cn

08:30-17:00 from Monday to Saturday