- EPP is also called Expanded polypropylene. It is also short for a new type of foam plastic.

- EPP is polypropylene plastic foam material, which is a kind of high crystallization polymer/gas composite material with excellent performance, and has become a new type of environmental protection compressive buffer heat insulation material with its unique and superior performance.

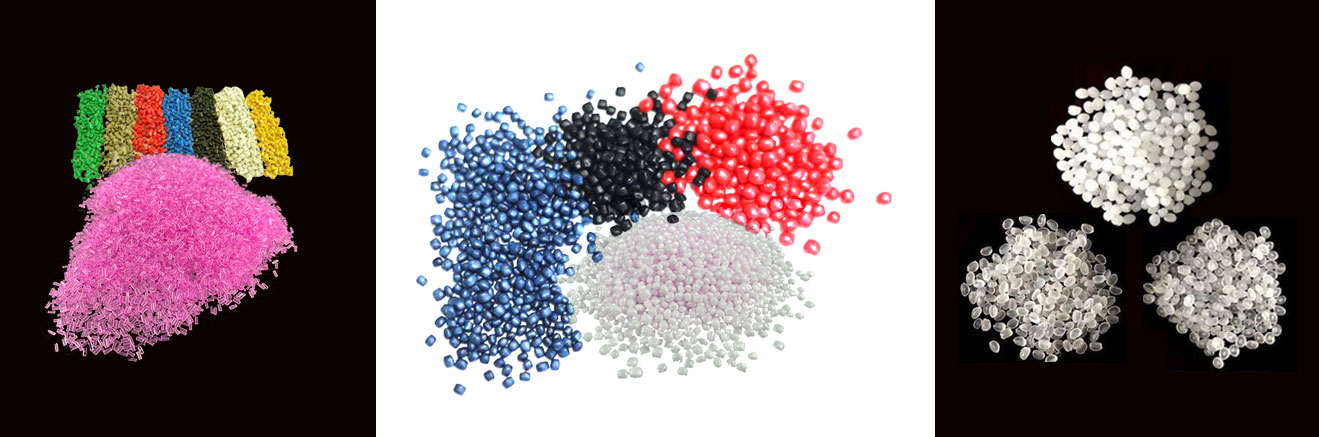

- Epps have the characteristics of light weight, strong plasticity, good shock absorption, and are widely used in automotive, aviation, electronics and other fields.

EPP is also called Expanded polypropylene. It is also short for a new type of foam plastic. EPP is polypropylene plastic foam material, which is a kind of high crystallization polymer/gas composite material with excellent performance, and has become a new type of environmental protection compressive buffer heat insulation material with its unique and superior performance.

Epps have the characteristics of light weight, strong plasticity, good shock absorption, and are widely used in automotive, aviation, electronics and other fields.

● Low density, epp density is 0.02-0.06g/cm3.

● Good thermal stability and high glass transition temperature.

● Epp shows excellent mechanical properties at the temperature of 80 degrees, epp elastic modulus is 150mpa.

● Epp has good shock absorption effect, can effectively absorb shock.

Porous structure, epp structure is composed of many small holes, this porous structure can effectively improve the shock absorption, reduce the impact force, the staggered structure of epp can make its elastic recovery ability stronger, but also improve its wear resistance.

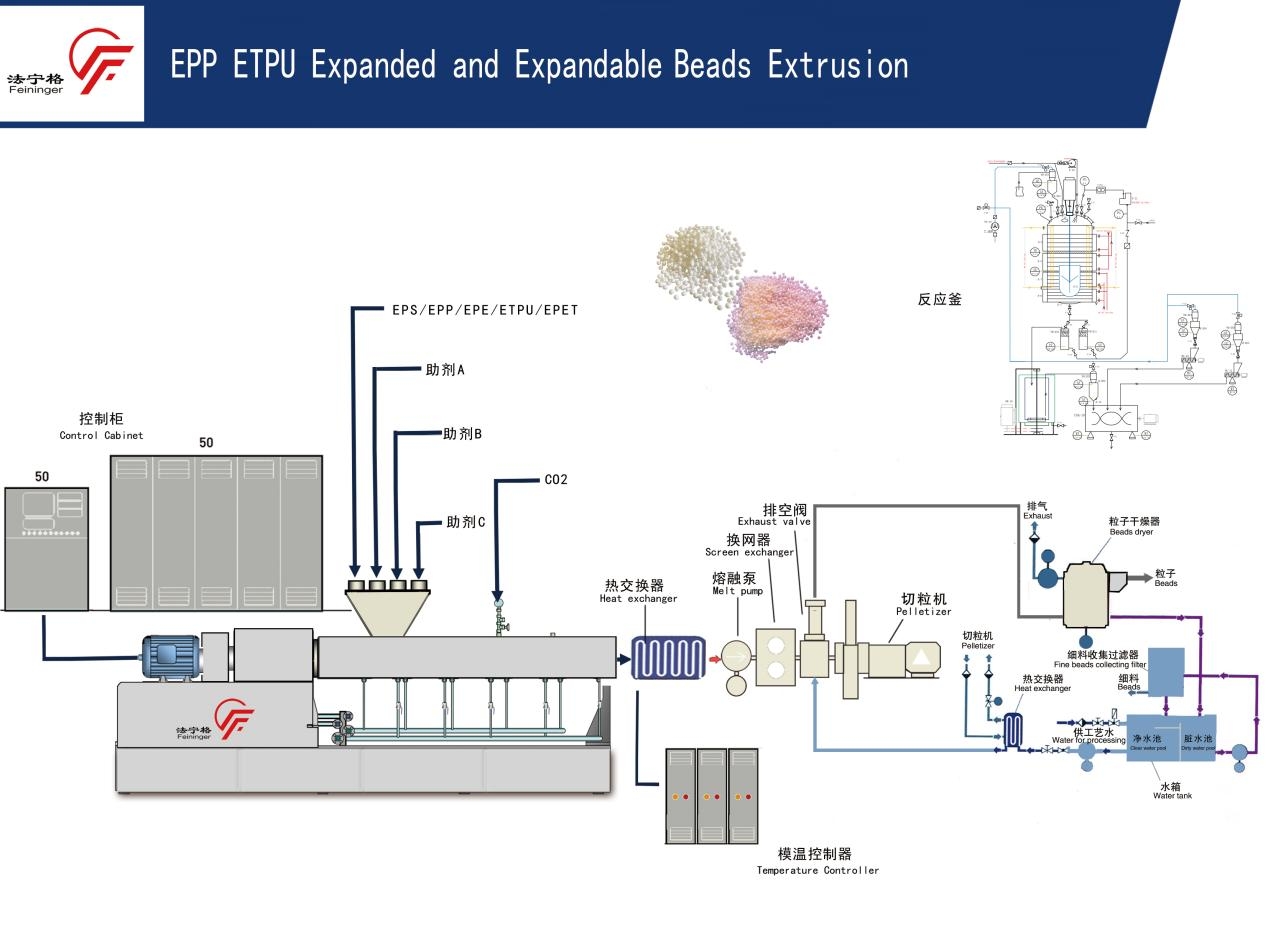

Traditional two-step process:pp was drawn and cut into particles. The raw material is impregnated in a CO2 foam kettle, and then rapidly expanded and foamed to form foam beads.

Feininger one-step method: In the process of pp raw material hot processing, directly add CO2 foaming agent, and directly make epp foam beads by underwater granulating and foaming.

Jiangsu Polymer Physics Foaming Engineering Technology Center belongs to Feininger Co., LTD., the supercritical CO2 single machine developed to produce EPP foaming beads at one time, and the production cost is controlled by 70% of the original production process cost. Compared with the traditional autoclave production method, this technical solution has less investment, simple production equipment, and short investment recovery, providing an easy to implement investment plan for upstream and downstream industries, and obtaining a rapid return on investment. As a result, companies can offer EPP parts at more competitive prices, while supporting the adoption of polyolefin that is easy to recycle. Other benefits include full control over EPP characteristics such as bulk density, closed cell content and bead size distribution, as well as maximum flexibility when fine-tuning the formulation. Moreover, the highly automated process reduces maintenance requirements and simplifies operations. In addition, the extruded beads can then be easily processed at standard steam pressure in a steam box forming machine to obtain a molded bead foam product with a specific shape. Feininger EPP supercritical CO2 primary foaming technology is a major technological breakthrough, so that the development of the industry has a qualitative leap.

EPP came out more than ten years of rapid development, but because of the one-step extrusion foam production technology is difficult to high, most companies can only use the autoclave method of production.EPP has been widely used in the packaging industry, especially in the packaging of export products, and has become an irreplaceable packaging according to the requirements of environmental protection.

Because of its non-toxic and high temperature resistance, it is also widely used in food packaging and microwave heating,IT products, electronic communication equipment, liquid crystal display, plasma color TV, precision electronic components, precision instrumentation, etc., have begun to use EPP as packaging materials, and another particularly important application field is in the automotive industry, high-speed rail, Marine ships and other fields of large number of applications.

Recommended Products

Inquiry

For the purchase, use, repair and maintenance of the product, you can contact us here

Solve parts, after-sales and service related problemsgo and have a look~

Send email to Feininger customer service centermarket@feininger.cn

08:30-17:00 from Monday to Saturday