Technology

01

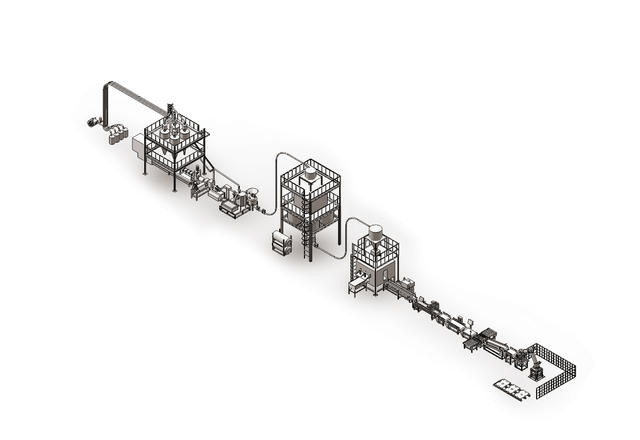

Dec . 2023Are you in the manufacturing industry and looking for ways to boost efficiency while saving on costs? Look no further than the revolutionary EPS Beads Foam Extrusion Line. This cutting-edge technology is transforming the way businesses produce foam products, offering a multitude of benefits that can enhance productivity and streamline operations.

In this blog post, we will explore what EPS beads are and how they work, as well as delve into the various advantages of using an EPS Beads Foam Extrusion Line. From cost savings to energy efficiency, this innovative solution has become a game-changer for industries across the board. So let's dive in and discover how you too can maximize your efficiency with this incredible machine!

EPS beads, also known as expanded polystyrene beads, are tiny spherical particles made from polystyrene resin. These beads have unique properties that make them versatile and widely used in various industries. So how do EPS beads work?

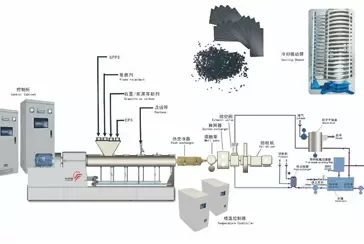

To begin with, the manufacturing process of EPS beads involves expanding the raw material through steam or a blowing agent. This expansion creates air pockets within the bead structure, making them lightweight and buoyant. The resulting foam is then molded into different shapes for different applications.

The working principle behind EPS beads is based on their excellent insulation properties. The air-filled cells within the bead structure trap heat, providing exceptional thermal insulation. This makes EPS beads ideal for packaging materials to protect fragile items during transit or storage.

Moreover, EPS beads also possess great cushioning capabilities due to their resilience and shock-absorbing qualities. They can effectively absorb impact energy and prevent damage to delicate products like electronics or glassware.

In addition to packaging, EPS beads are extensively used in construction as an insulating material for roofs, walls, and floors. Their lightweight nature reduces structural load while maintaining superior thermal performance.

Furthermore, these versatile foam particles find application in flotation devices such as life jackets and buoys because they are both water-resistant and buoyant.

Understanding how EPS beads work allows us to appreciate their incredible versatility across multiple industries. From protecting valuable goods during transportation to enhancing energy efficiency in construction projects – these small but mighty foam particles play a crucial role in maximizing efficiency across various sectors!

The benefits of using an EPS Beads Foam Extrusion Line are numerous and can greatly enhance the efficiency of your production process. One major advantage is the ability to customize the size and density of foam beads, allowing for greater flexibility in meeting specific project requirements. This versatility ensures that you can produce foam products that perfectly match your customer's needs.

Another benefit is the speed at which EPS beads can be extruded. With a high-speed extrusion line, you can significantly increase productivity, reducing production time and costs. This means more output in less time, leading to higher profits for your business.

Additionally, EPS beads foam extrusion lines offer excellent energy efficiency. These machines are designed with advanced technology to minimize energy consumption while maintaining optimal performance levels. By utilizing cutting-edge insulation materials and efficient heating systems, these lines help reduce electricity usage without compromising on quality.

Furthermore, using an EPS Beads Foam Extrusion Line promotes sustainability as it enables recycling of waste materials into new foam products. Waste polystyrene can be reprocessed through granulation and transformed into reusable raw material for manufacturing new foam items. This not only reduces environmental impact but also contributes positively towards a circular economy.

Investing in an EPS Beads Foam Extrusion Line brings multiple advantages including customization capabilities, increased productivity, energy savings,and promoting sustainability through waste reduction and recycling processes

Cost and energy savings are significant advantages of using an EPS Beads Foam Extrusion Line. This innovative machine is designed to maximize efficiency and minimize waste, resulting in substantial cost reductions for manufacturers.

One of the primary ways that an EPS Beads Foam Extrusion Line saves costs is through its efficient use of raw materials. The machine operates by melting polystyrene beads and then extruding them into a foam product. This process allows for precise control over the amount of material used, minimizing waste and reducing production costs.

In addition to material savings, an EPS Beads Foam Extrusion Line also offers energy savings. These machines are equipped with advanced heating technology that ensures optimal temperature control during the extrusion process. By efficiently managing heat distribution, the machine consumes less energy compared to traditional manufacturing methods.

Furthermore, the foam products produced by an EPS Beads Foam Extrusion Line have excellent thermal insulation properties. This means that they provide superior insulation against heat transfer, helping to reduce energy consumption in buildings where these products are used as insulation materials.

Investing in an EPS Beads Foam Extrusion Line can lead to significant cost and energy savings for manufacturers across various industries. Not only does it minimize material waste, but it also reduces energy consumption while delivering high-quality foam products with exceptional thermal insulation properties.

The versatility of EPS beads foam extrusion line makes it an invaluable asset across a wide range of industries. From construction to packaging, this innovative technology is revolutionizing the way businesses operate. Let's explore some of the key applications:

1. Construction Industry: EPS beads foam extrusion line plays a crucial role in the construction industry by providing lightweight and insulating materials for buildings. The expanded polystyrene (EPS) foam produced by this machine is widely used as insulation boards, concrete forms, void fillers, and even decorative elements.

2. Packaging Industry: With its exceptional cushioning properties, EPS foam produced from this extrusion line is ideal for protecting fragile items during transportation. It ensures that delicate products such as electronics, glassware, or artwork arrive at their destinations intact.

3. Automotive Industry: EPS foam is also employed in the automotive sector due to its excellent energy absorption capabilities. It can be found in various car components like bumpers, headrests, door panels, and interior trims.

4. Agriculture Sector: In agriculture, EPS foam sheets are used for thermal insulation purposes within greenhouses to regulate temperature and minimize heat loss during colder seasons.

5. Food Service Industry: Restaurants and food service providers utilize EPS containers made from these machines for takeout orders or storing perishable items like seafood or ice cream due to their excellent thermal insulation qualities.

6. Medical Sector:Eps foams are extensively used in medical facilities for packaging sensitive instruments & equipment which need protection against damage from impacts

7. Electronics Industry:The electrical appliances manufacturing companies use eps foams manufactured by these machines because they provide superior shock resistance & protect electronic devices during shipping & handling

By exploring these diverse applications across multiple industries it becomes evident how valuable an investment an EPS beads foam extrusion line can be! Its efficiency allows businesses to optimize productivity while simultaneously reducing costs and energy consumption.

Proper maintenance and upkeep are essential for ensuring the smooth operation of an EPS Beads Foam Extrusion Line. By following a regular maintenance schedule, you can maximize efficiency and extend the lifespan of your machine.

One crucial aspect of maintenance is cleaning. Regularly clean all components to remove any dust, debris, or residue that may accumulate during production. This will help prevent clogs or blockages in the system and ensure optimal performance.

In addition to cleaning, it is important to inspect the machine regularly for any signs of wear or damage. Pay close attention to key areas such as heating elements, cooling systems, and extrusion dies. Replace any worn-out parts promptly to avoid downtime and maintain productivity.

Another crucial aspect of machine upkeep is lubrication. Proper lubrication helps reduce friction between moving parts, preventing premature wear and tear. Follow manufacturer guidelines for lubricating different components to ensure smooth operation.

Consider investing in routine professional servicing by experts like Feininger who specialize in EPS Beads Foam Extrusion Lines. Their expertise can identify potential issues before they become major problems, saving you time and money in the long run.

By prioritizing regular cleaning, inspection, lubrication, and professional servicing when needed, you can keep your EPS Beads Foam Extrusion Line running efficiently for years to come!

In today's fast-paced and competitive market, maximizing efficiency is crucial to the success of any business. With the EPS Beads Foam Extrusion Line, companies can achieve just that and more. This advanced machine offers a wide range of benefits that make it a valuable investment for various industries.

The use of EPS beads in foam extrusion has revolutionized the manufacturing process by providing exceptional insulation properties and lightweight construction materials. The versatility of EPS beads allows for customization to meet specific requirements, making it an ideal choice for industries such as packaging, construction, automotive, and more.

One of the major advantages of using an EPS Beads Foam Extrusion Line is its cost and energy savings. The efficient design ensures minimal material wastage while reducing energy consumption during production. This not only translates to lower operating costs but also contributes to a greener environment by minimizing waste generation.

Furthermore, this innovative machine enables businesses to improve their productivity with faster cycle times and higher output rates. Its automated features allow for continuous operation with minimal human intervention, increasing overall efficiency and reducing labor costs.

Maintenance and upkeep of the EPS Beads Foam Extrusion Line are relatively easy compared to other complex machinery. Regular cleaning and inspection ensure smooth operations while preventive maintenance helps extend its lifespan significantly.

Investing in an EPS Beads Foam Extrusion Line can provide numerous advantages in terms of efficiency, cost savings, productivity improvement, versatile applications across various industries like packaging or automotive sectors etc., making it a wise choice for businesses looking to stay ahead in today's competitive market landscape. Feininger is one manufacturer known for producing high-quality machines that offer exceptional performance and reliability.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

17 Apr 2024

17 Apr 2024 Enhancing Product Quality: Applications of the Micro Supercritical CO₂&N₂ Injection Machine

In the realm of polymer processing and manufacturing, the Micro Supercritical CO₂&N₂ Injection Machine from China Feininger has revolutionized the industry with its ability to enhance product quality across various applications.

16 Apr 2025

16 Apr 2025 Streamlining Production with Feininger's EPS Beads Foam Extrusion Line

In the world of foam production, precision and consistency are key to achieving high-quality products. Whether it's for packaging, insulation, or construction applications, Expanded Polystyrene (EPS) foam plays a crucial role in numerous industries.

11 Apr 2025

11 Apr 2025 Advanced Technology in EPS Beads Foam Production: A Look at Feininger’s Cutting-Edge Solutions

In the world of foam production, particularly EPS (Expanded Polystyrene), technology plays a crucial role in determining product quality, operational efficiency, and overall cost-effectiveness.