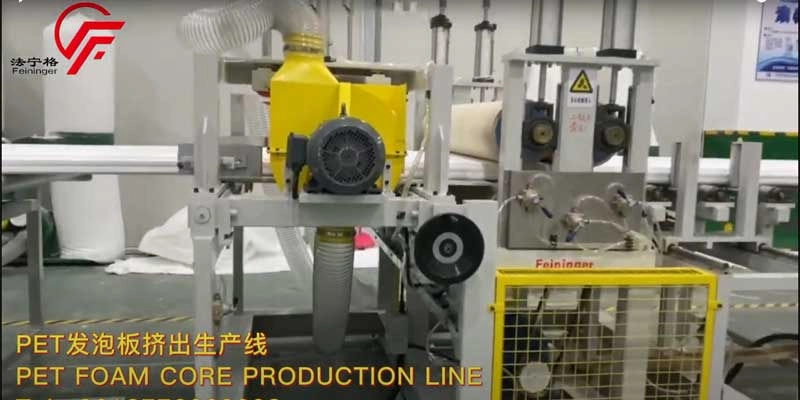

Feininger PET sheet extrusion line are designed to ensure high performance, low energy consumption, durability and versatility for companies in the plastics industry. Each PET sheet extrusion line is modular and every detail can be customized, thanks to Feininger's accessories and machines: the best technology to ensure high productivity and long-term stable performance. With the continuous improvement of performance level, Feininger's experience and continuous research on technology and solutions, plastic material extruders improve the productivity of the production line, reducing costs and energy consumption.

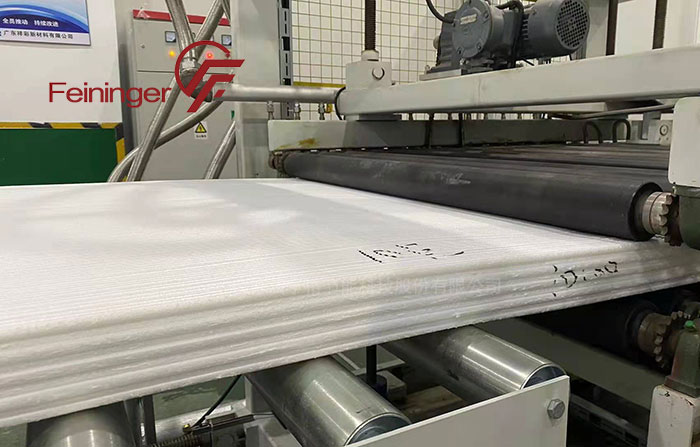

The main ingredient of PET foamed board is compulsory Polyethylene terephthalate, commonly known as polyester resin.The application of advanced foaming technology, carbon dioxide foaming. Traditional foam used in the production of fluoride as foaming agent, will have an impact on the environment and human health, ning, PET sheet extrusion line using composite foaming agent "CO2" replaces "fluorine series" foaming agent, greatly reduce the production cost, and CO2 as foaming agent is more environmental protection, can achieve zero emissions of greenhouse gases.

In addition, PET foamed board can be recycled, so it has good environmental protection performance, which is very conducive to environmental protection and more conducive to sustainable development.

PET foam board is an emerging application with great potential. It has good shear resistance, thermal insulation performance, good heat resistance, mechanical strength and other advantages, as well as environmental protection performance. Therefore, it is often used in the field of building thermal insulation materials, sandwich structure material core materials, sports equipment, fan blades, ships, aerospace and other fields.As a thermoplastic engineering material, PET has good mechanical properties, electrical insulation, chemical and creep resistance, fatigue and friction resistance, etc. It is widely used in daily consumption, transportation, sports equipment and biomedical and other important fields.

Advanced Technology

Perfectly realized the equipment structure of double-section machine for product production, and the capacity is increased on the basis of ensuring the product production process.

High Performance-Cost Ratio

After one year's experiment, Feininger company has realized the full localization from material processing, screw structure of main extruder, pressure temperature control, mold forming to post-processing adhesion, thus greatly reducing the manufacturing cost of equipment, and on the premise of ensuring quality, its cost is far lower than similar foreign equipment.

After-sales Guarantee

As the R&D company and manufacturer of PET foaming board production line, Feininger company can provide comprehensive product production process training and continuous technical guidance for customers.

CO2 Foaming

Traditional foam agent used in the PET foam core production line is fluoride, which has an impact on the environment and human health. However, our PET extrusion line can use composite foaming agent "CO2" to replace "fluorine series" foaming agent, which not only will greatly reduce the production cost but also can achieve zero emissions of greenhouse gases.

Recommended Products

Inquiry

For the purchase, use, repair and maintenance of the product, you can contact us here

Solve parts, after-sales and service related problemsgo and have a look~

Send email to Feininger customer service centermarket@feininger.cn

08:30-17:00 from Monday to Saturday