As a leading TPU Underwater Pelletizer manufacturer based in China, China Feininger specializes in advanced polymer processing equipment designed to optimize efficiency and product quality. Our TPU Underwater Pelletizer systems integrate cutting-edge technology to meet the diverse needs of polymer manufacturers worldwide.

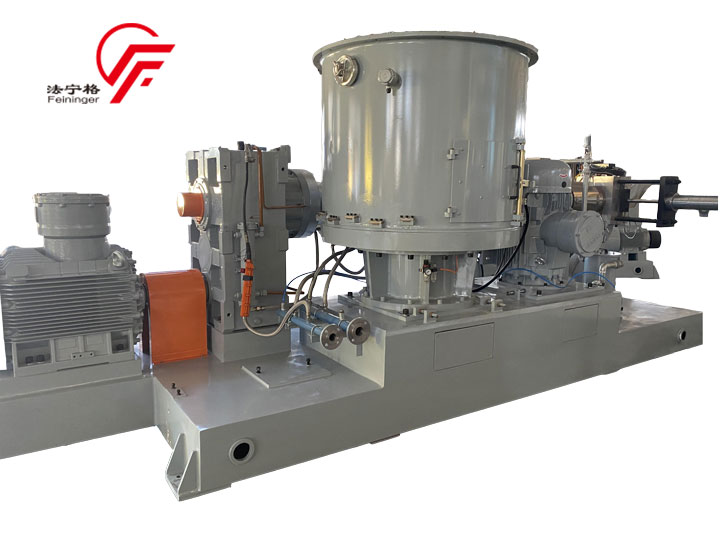

The main machine of TPU underwater granulator is extruder system, which is composed of extrusion system, transmission system and heating and cooling system. Extrusion system: extrusion system includes screw, barrel, hopper, head and die. The plastic is moulded into an average melt by an extrusion system and is continuously extruded by a screw under pressure established during the process.

The thermal relative edge formwork technology of the TPU underwater pelletizer system can constantly heat the material carrier, and the thermal relative edge technology does not allow the melt to "condense" in the die hole. And it is not sensitive to pressure fluctuations in the extruder, making the pelleting process very reliable and more efficient. In addition, our designs are simpler and our water treatment and drying systems operate more efficiently. Continuous filtration process water quality, lower maintenance costs. The design of the dryer has no blind spots, all the filters are quick disassembly, and the TPU underwater granulation machine makes it easy to change the material and color. The complete underwater pelleting system can be easily adapted to different production strips to increase production flexibility.

TPU underwater granulation process realizes automatic granulation, convenient operation, good particle quality, and has lower energy consumption and production cost and larger production space advantages than traditional strip granulation. The underwater granulator can be used for a large number of polymers, and is more suitable for low viscosity or adhesive polymers. Suitable for TPU, PP, PE, PS, TPE and other elastomers, masterbatch filling, chemical raw materials and modified granulation and cutting.

Feininger underwater granulation system, scientific design, stable pressure, accurate temperature control, unique template design to ensure the ideal insulation effect, effectively solve the temperature difference between temperature and water caused by the template due to condensation and cavitation caused by plastic particles, and prevent the melt in the exit hole "shape", and because the granulation process is almost no fluctuation, the process is very reliable, The heat loss is more effectively reduced by 95%.

Thermal Relative Edge Formwork Technology: Our proprietary technology maintains optimal temperatures within the material carrier, preventing melt condensation in die holes. This feature enhances reliability and efficiency, reducing downtime and ensuring consistent pellet quality.

Efficient Water Treatment and Drying Systems: Designed for seamless operation, our systems feature advanced water treatment and drying technologies. Continuous filtration of process water and quick-disassembly filters minimize maintenance costs and enhance operational efficiency.

Production Flexibility: China Feininger's TPU Underwater Pelletizer systems are versatile, easily adapting to various production requirements and polymer types. This flexibility allows manufacturers to optimize production processes and meet changing market demands effectively.

Automatic Granulation and Ease of Operation: With automated granulation capabilities, our systems streamline production processes while maintaining high standards of pellet quality. Operators benefit from user-friendly controls and precise process management.

At the heart of our TPU Underwater Pelletizer systems lies advanced extrusion technology. The extruder system, comprising a precision-engineered screw, barrel, hopper, head, and die, ensures uniform melt formation under controlled conditions. This process is essential for producing high-quality pellets consistently.

Energy Efficiency: Reduced energy consumption compared to traditional granulation methods translates into lower production costs and improved sustainability.

Cost Effectiveness: Enhanced operational efficiency and minimized downtime contribute to overall cost savings over the equipment's lifecycle.

Superior Product Quality: Consistent pellet size and shape meet stringent industry standards, ensuring product reliability and customer satisfaction.

China Feininger is your trusted partner for TPU Underwater Pelletizer solutions, combining technological innovation with manufacturing expertise. Whether you're looking to enhance production efficiency, reduce costs, or improve product quality, our TPU Underwater Pelletizer systems deliver reliable performance and unmatched versatility.

Explore how our advanced polymer processing solutions can elevate your manufacturing capabilities. Contact us today to learn more about our TPU Underwater Pelletizer systems and discover the difference China Feininger can make for your business.

Recommended Products

Inquiry

For the purchase, use, repair and maintenance of the product, you can contact us here

Solve parts, after-sales and service related problemsgo and have a look~

Send email to Feininger customer service centermarket@feininger.cn

08:30-17:00 from Monday to Saturday