Technology

13

Mar . 2024In the world of protective packaging and lightweight construction materials, Expanded Polypropylene (EPP) beads stand out for their exceptional properties. However, the efficiency and cost-effectiveness of producing these beads are largely dependent on the technology used in the manufacturing process. Feininger, a leading name in the industry, is revolutionizing the production of EPP beads with its advanced machines and innovative approach.

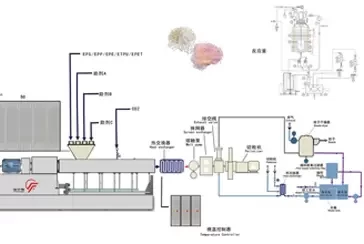

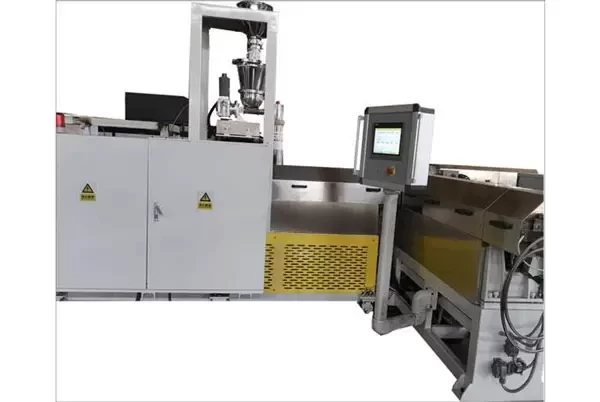

Feininger's EPP beads machines leverage a unique process that involves the direct addition of CO2 foaming agents to polypropylene (PP) raw materials during hot processing. This method, unlike traditional techniques, allows for the creation of EPP foam beads through underwater granulation and foaming. The result is a highly efficient and streamlined production process that not only yields superior quality beads but also significantly reduces energy consumption and costs.

One of the standout features of Feininger's technology is the use of supercritical CO2 in the single machine developed for EPP foaming beads production. This approach is a game-changer in the industry, as it eliminates the need for multiple stages and equipment typically required in conventional processes. By producing EPP beads in one go, Feininger's machine dramatically cuts down on production time and operational expenses.

The cost savings associated with Feininger's advanced EPP beads machines are substantial. The company has successfully managed to control the production cost to 70% of the original process cost. This reduction in expenses does not come at the expense of quality; on the contrary, the EPP beads produced using Feininger's technology exhibit superior characteristics, including enhanced strength, durability, and resilience.

Moreover, the environmental benefits of Feininger's approach cannot be overstated. The use of CO2 as a foaming agent is a more eco-friendly alternative to traditional chemical foaming agents. This not only aligns with global sustainability goals but also positions Feininger as a responsible and forward-thinking player in the industry.

In conclusion, Feininger's advanced EPP beads machines represent a significant leap forward in the production of expanded polypropylene. By maximizing efficiency, reducing costs, and prioritizing environmental sustainability, Feininger is setting new standards in the industry and paving the way for more innovative and responsible manufacturing practices. For businesses looking to stay ahead in the competitive world of protective packaging and lightweight materials, embracing Feininger's technology is a smart and strategic move.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

29 Oct 2024

29 Oct 2024 How Feininger's Foam Sheet Laboratory Machine Enhances XPS Foam Research

In the rapidly evolving field of materials science, the need for advanced testing and research equipment is paramount. For researchers focused on extruded polystyrene (XPS) foam, the Foam Sheet Laboratory Machine from China Feininger stands out as an invaluable tool.

13 Jun 2024

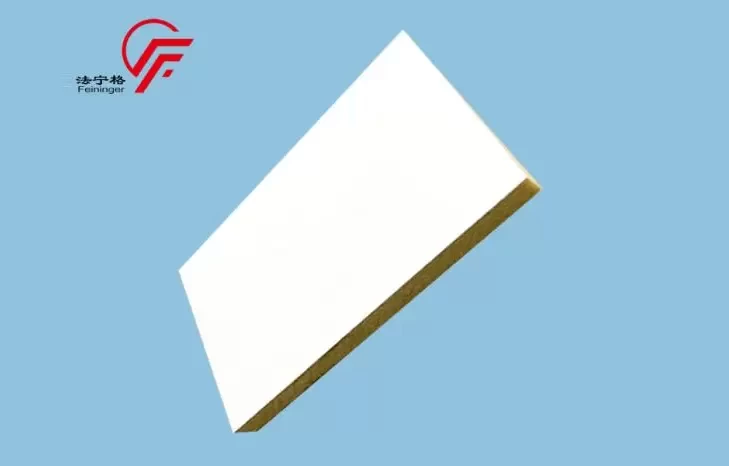

13 Jun 2024 Unveiling the Advantages of XPS with PVC Sandwich Panels in Construction

Are you looking for a game-changing solution to revolutionize your construction projects? Look no further than XPS with PVC sandwich panels. These innovative panels are making waves in the industry, offering a host of benefits that can enhance both the efficiency and sustainability of your building endeavors.

19 Jun 2024

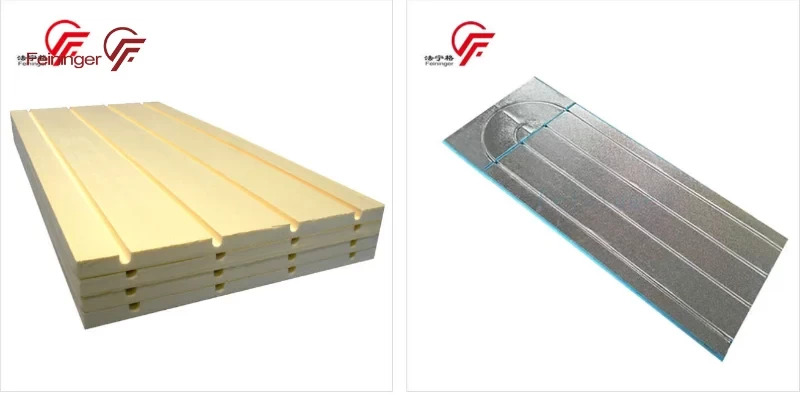

19 Jun 2024 Comparing Insulation Materials: Where Does XPS Foam Board with Aluminum Foil Stand?

In the world of insulation materials, the choices can seem endless. Among these, XPS (Extruded Polystyrene) foam board with aluminum foil has become a significant player, particularly in scenarios requiring robust thermal resistance and moisture protection.