Technology

26

Feb . 2024Feininger, the pioneering manufacturer of XPS Extrusion Line and XPS Foam Board based in China, is poised to make a significant impact at the highly anticipated UzBuild - Uzbekistan International Exhibition 2024. Set against the backdrop of the esteemed Uzekspocentre Exhibition Centre in Tashkent from February 27 to March 1, 2024, this premier event will spotlight the latest advancements across various sectors, including Building machinery, Refurbishment, Textiles, Home textiles, and Construction.

Feininger, renowned for its innovation and expertise in XPS Foam technology, will take center stage, showcasing an impressive array of cutting-edge equipment designed to revolutionize the construction and manufacturing industries. Among the flagship products to be featured at the exhibition are the XPS Foam Board Production Line, PS Foam Sheet Extrusion Line, PS Skirting Board Production Line, and XPS Cornice Moulding Production Line.

Visitors to Feininger's booth can expect to immerse themselves in a world of innovation and excellence, as the company unveils its latest advancements in XPS technology. The XPS Foam Board Production Line, a cornerstone of Feininger's product lineup, offers unrivaled precision and efficiency in the production of high-quality foam boards essential for insulation and construction applications. Meanwhile, the PS Foam Sheet Extrusion Line showcases Feininger's commitment to versatility, enabling the seamless production of foam sheets for a myriad of packaging and insulation needs.

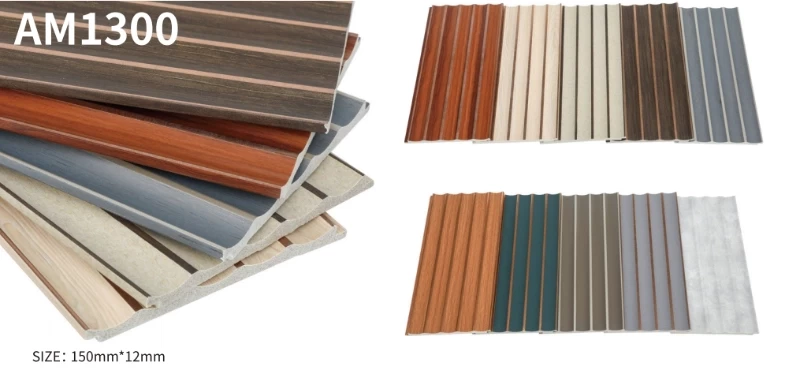

In addition to these groundbreaking solutions, Feininger will also spotlight its PS Skirting Board Production Line and XPS Cornice Moulding Production Line, catering to the growing demand for decorative and functional architectural elements. These state-of-the-art production lines empower manufacturers to craft intricate skirting boards and cornice moldings with unparalleled precision, elevating the aesthetic appeal of residential and commercial spaces alike.

"We are excited to unveil our latest innovations in XPS technology at UzBuild - Uzbekistan International Exhibition 2024," remarked a spokesperson for Feininger. "Our XPS Foam Board Production Line, PS Foam Sheet Extrusion Line, PS Skirting Board Production Line, and XPS Cornice Moulding Production Line represent the culmination of years of research, development, and expertise. We are confident that these cutting-edge solutions will empower our customers to achieve new heights of efficiency, quality, and performance in their respective industries."

Feininger extends a warm invitation to all attendees to visit their booth at UzBuild - Uzbekistan International Exhibition 2024 and discover firsthand the innovation, quality, and excellence that define their brand. With a steadfast commitment to pushing the boundaries of possibility, Feininger continues to shape the future of construction materials and architectural elements on a global scale.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

15 Aug 2024

15 Aug 2024 How PET Foam Core Production Lines Are Shaping the Future of Composite Materials

In the world of composite materials, the demand for lightweight, durable, and environmentally friendly solutions is growing rapidly. PET foam core production lines are at the forefront of this transformation, offering innovative and sustainable materials that meet the needs of various industries.

28 Mar 2024

28 Mar 2024 Transforming Spaces: The Versatility of Partition Wall Panels

In the ever-evolving world of interior design and architecture, the need for flexible and innovative solutions to divide and optimize spaces has never been more paramount. Partition wall panels have emerged as a versatile and efficient tool to meet this demand.

24 Nov 2023

24 Nov 2023 Supercritical CO2 Foaming Technology

Supercritical CO2 foaming technology is an environmentally friendly method that can reduce waste and harm to the environment to a great extent.