Technology

21

Aug . 2024In the world of materials science and product development, foam sheet laboratory machines play a critical role in research, testing, and small-scale production. Whether you’re a university researcher, part of a research institution, or working within an enterprise, having the right equipment is essential for obtaining reliable results and optimizing product performance. When selecting a foam sheet laboratory machine, it’s important to understand the key features that can enhance flexibility, accuracy, and efficiency. In this article, we’ll explore the innovative features you should look for in a foam sheet laboratory machine, with a focus on the cutting-edge solutions provided by Feininger.

A critical factor in choosing the right foam sheet laboratory machine is its ability to handle various thermoplastic materials such as PBAT, PA, and PET. Flexibility in material processing allows researchers and developers to experiment with different formulations and production conditions, making the equipment more valuable across a wide range of applications. Feininger’s Thermoplastic Physical Foaming Test Equipment is designed with this versatility in mind. It accommodates a wide spectrum of materials, ensuring that you have the freedom to test and develop innovative solutions that meet your specific needs.

Accurate control over temperature, pressure, and other processing parameters is crucial for successful material testing and development. Advanced foam sheet laboratory machines offer precise control systems that allow users to fine-tune the conditions of each experiment. This level of control ensures that the results are reliable and replicable, which is essential for both academic research and commercial product development. Feininger’s laboratory machines are equipped with state-of-the-art control systems, providing the exact measurements and adjustments needed to optimize your research outcomes.

In research and development environments, space is often a premium. Laboratory machines should be compact enough to fit into smaller workspaces without compromising on performance. Feininger’s Thermoplastic Physical Foaming Test Equipment is specifically designed for laboratory use, making it ideal for universities, research institutions, and enterprises with limited space. Despite its compact size, the machine offers robust capabilities, ensuring that researchers can perform high-quality testing without needing a large-scale production facility.

One of the standout features of Feininger’s foam sheet laboratory machines is their dual functionality—providing both basic scientific research conditions and supporting pilot testing. This capability is essential for organizations that aim to scale up from laboratory experiments to industrial production. The equipment is engineered to replicate industrial production conditions on a smaller scale, allowing researchers to gather critical data that can be directly applied to larger-scale manufacturing processes. This scalability is a significant advantage, particularly for enterprises looking to transition from R&D to commercial production.

Ease of use is another important consideration when selecting a foam sheet laboratory machine. Modern machines are equipped with intuitive interfaces that simplify operation, enabling users to quickly set parameters, monitor processes, and collect data. Feininger places a strong emphasis on user experience, offering machines with easy-to-navigate control panels and integrated data logging features. This combination of convenience and functionality makes it easier for researchers to analyze results and make informed decisions based on comprehensive data.

When investing in laboratory equipment, durability and reliability are key factors. The materials and construction of the machine should withstand rigorous use in a research environment while maintaining consistent performance over time. Feininger has a reputation for producing high-quality equipment that delivers reliable results, even after extended use. Their machines are built to last, offering long-term value for institutions and enterprises that require dependable testing solutions.

Feininger is a leader in the development of thermoplastic physical foaming test equipment, providing innovative solutions tailored to meet the needs of universities, research institutions, and industrial enterprises. Their equipment is designed with a focus on flexibility, precision, and scalability, ensuring that researchers have the tools they need to push the boundaries of material science and product development.

Selecting the right foam sheet laboratory machine is a critical decision that can impact the success of your research and development projects. By prioritizing features such as flexibility, precision, scalability, and ease of use, you can ensure that your equipment meets the demands of both academic and industrial applications. Feininger’s Thermoplastic Physical Foaming Test Equipment offers all these benefits and more, making it a top choice for institutions and enterprises committed to innovation and excellence.

For more information on Feininger's foam sheet laboratory machines and how they can support your research and development efforts, visit our website or contact our team today.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

27 Jun 2024

27 Jun 2024 Choosing the Right TPU Underwater Pelletizer for Your Manufacturing Needs

In the realm of polymer processing, selecting the appropriate equipment can significantly impact efficiency, product quality, and overall operational costs. When it comes to TPU (Thermoplastic Polyurethane) underwater pelletizers, making an informed decision is crucial to meeting production goals effectively.

28 Mar 2024

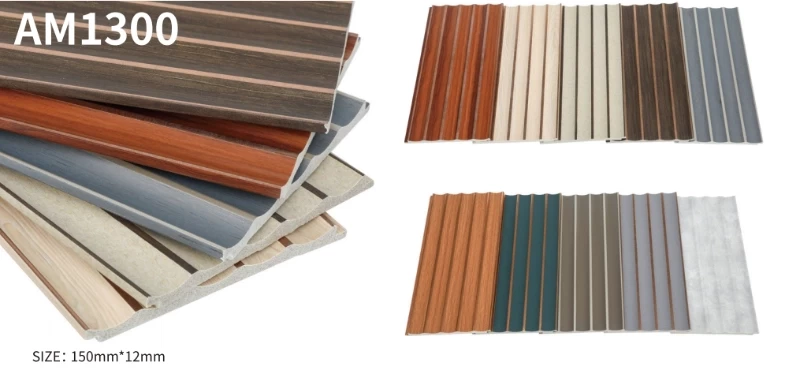

28 Mar 2024 Transforming Spaces: The Versatility of Partition Wall Panels

In the ever-evolving world of interior design and architecture, the need for flexible and innovative solutions to divide and optimize spaces has never been more paramount. Partition wall panels have emerged as a versatile and efficient tool to meet this demand.

10 Oct 2023

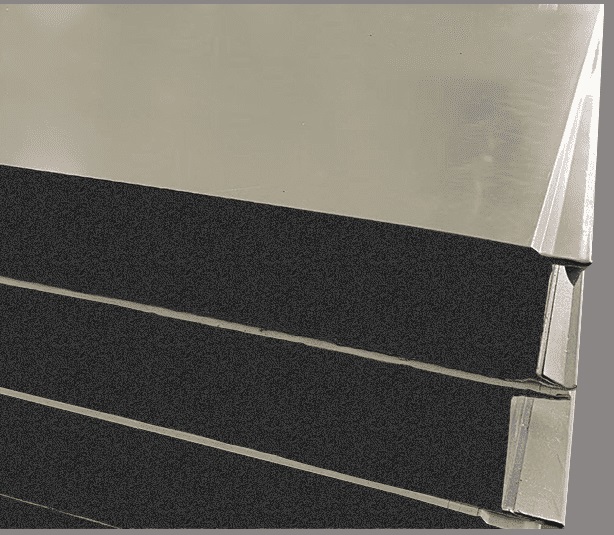

10 Oct 2023 Graphene polystyrene insulation sandwich panel (GPI)

Graphene polystyrene insulation sandwich panel (GPI) refers to a rigid foam with closed-cell structure formed by extrusion and foaming, with polystyrene resin or its copolymer as the main component, adding graphene and other additives.