Technology

30

Jul . 2024Proper maintenance of your beads foam experiment machine is essential to ensure its longevity and optimal performance. Whether used in universities, research institutions, or industrial production lines, keeping your equipment in top shape can save you time, money, and headaches. China Feininger, a leading provider of PBAT/PA/PET and other thermoplastic physical foaming test equipment, offers expert advice on how to maintain your beads foam experiment machine effectively.

Regular cleaning is crucial to prevent buildup of residues that can affect the performance of your beads foam experiment machine. Residues can cause blockages and affect the accuracy of your experiments.

Regular inspections help identify wear and tear early, allowing for timely repairs and replacements. This can prevent unexpected breakdowns and extend the lifespan of your machine.

Proper lubrication of moving parts reduces friction, preventing wear and ensuring smooth operation. It also helps maintain the accuracy and precision of the machine.

Regular calibration ensures that your beads foam experiment machine provides accurate and reliable results. This is particularly important in research and industrial applications where precision is critical.

Keeping the machine's software up to date ensures you have the latest features, improvements, and security patches. This can enhance the machine’s performance and prevent software-related issues.

Professional servicing ensures that your beads foam experiment machine is maintained to the highest standards. Technicians can perform detailed inspections and repairs that may be beyond routine maintenance.

Maintaining your beads foam experiment machine is essential for its longevity and performance. By following these maintenance tips from China Feininger, you can ensure that your PBAT/PA/PET and other thermoplastic physical foaming test equipment remains in optimal condition, providing accurate and reliable results for your research or production needs. Regular cleaning, inspections, lubrication, calibration, software updates, and professional servicing are all critical components of an effective maintenance routine.

For more information on maintaining your beads foam experiment machine or to learn about China Feininger's range of thermoplastic physical foaming test equipment, visit our website or contact our support team today.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

13 Oct 2023

13 Oct 2023 See You At The 134rd China Import and Export Fair

The China Import and Export Fair (Canton Fair), founded on April 25, 1957, is held in Guangzhou every spring and autumn, jointly sponsored by the Ministry of Commerce and the People's Government of Guangdong Province, and undertaken by China Foreign Trade Center.

22 Nov 2024

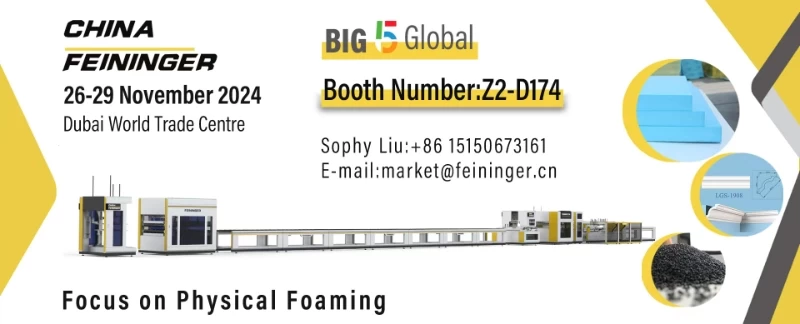

22 Nov 2024 China Feininger at BIG 5 Global 2024: Showcasing Cutting-Edge XPS Foam Board Technology

China Feininger, a leading manufacturer in the field of extrusion lines for XPS (Extruded Polystyrene) foam boards, is set to attend the highly anticipated BIG 5 Global event in Dubai.

18 Jan 2024

18 Jan 2024 Boost Efficiency and Quality with the XPS Cornice Production Line

Welcome to the world of efficient and high-quality cornice production with the XPS Cornice Production Line! If you're in the construction or interior design industry, you know that creating beautiful and intricate cornices can be a time-consuming and labor-intensive task.