Technology

05

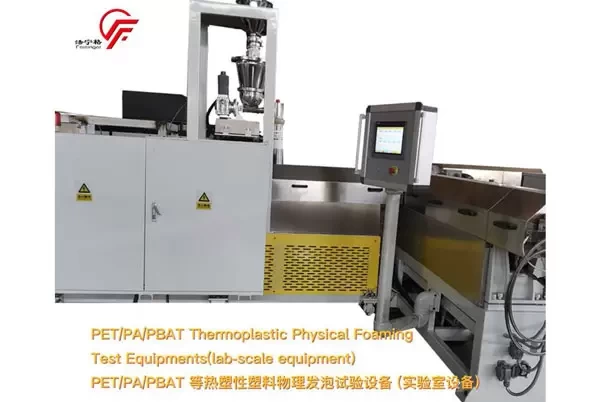

Mar . 2025As industries strive for efficiency, cost reduction, and sustainability, PET foam sheet production has emerged as a cutting-edge solution. China Feininger, a leading manufacturer in XPS and PET foam extrusion technology, has developed high-performance PET foam sheet production lines that not only enhance manufacturing efficiency but also significantly reduce environmental impact.

With advanced foaming technology and the use of CO₂ as a foaming agent, Feininger's PET foam sheet production line provides a cost-effective, eco-friendly alternative to traditional foam manufacturing methods.

Traditional foam production relies on fluorine-based foaming agents, which contribute to environmental pollution and health hazards. Feininger's PET foam sheet production line replaces fluorine-based agents with CO₂ foaming, achieving:

✅ Zero greenhouse gas emissions

✅ Compliance with environmental standards

✅ Safer working conditions

By utilizing CO₂ as a foaming agent, Feininger significantly reduces carbon footprint while maintaining the highest quality in foam sheet production.

Fluorine-based foaming agents are not only harmful but also expensive due to strict environmental regulations. Feininger's CO₂-based composite foaming technology lowers production costs while maintaining superior product performance. This cost-saving advantage makes PET foam sheets an economically viable option for manufacturers worldwide.

Feininger's PET foam sheets are known for their lightweight structure, high strength, and durability. These sheets offer:

✔ Superior mechanical properties

✔ Thermal and chemical resistance

✔ Excellent adhesion for composite applications

This makes them ideal for industries such as automotive, aerospace, construction, and packaging, where high-strength and eco-friendly materials are essential.

Feininger's PET sheet extrusion line is designed for optimal material utilization, significantly minimizing raw material waste. By leveraging advanced processing techniques, Feininger ensures:

This precision-driven process enhances production capacity while reducing unnecessary waste, making it a sustainable and cost-effective choice for manufacturers.

Unlike traditional foam materials, PET foam sheets can be fully recycled, contributing to a circular economy. Feininger's production process supports:

♻ Reprocessing of PET waste into new sheets

♻ Reduction of landfill waste

♻ Sustainable raw material sourcing

By choosing Feininger's PET foam sheet production line, manufacturers align with global sustainability goals, ensuring a greener future for industrial production.

China Feininger is an industry leader in PET and XPS foam extrusion technology, offering:

✅ State-of-the-art PET foam sheet production lines

✅ Innovative CO₂ foaming technology for sustainability

✅ High-efficiency, cost-saving manufacturing solutions

✅ Comprehensive technical support & free training

With years of expertise in extrusion molding, Feininger provides turnkey solutions that ensure stable, reliable, and high-quality PET foam sheet production.

Feininger's PET foam sheet production line is revolutionizing the industry by delivering:

✔ Eco-friendly CO₂ foaming technology

✔ Lower production costs & higher efficiency

✔ High-performance PET foam sheets for multiple applications

✔ Sustainable manufacturing with minimal waste

By investing in Feininger's PET foam sheet production line, manufacturers can achieve long-term cost savings, enhanced product quality, and environmentally responsible production.

Would you like to learn more about Feininger's PET foam extrusion solutions? Contact us today for expert consultation and tailored production solutions!

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

22 Aug 2024

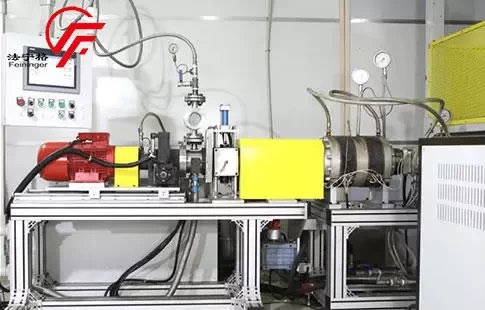

22 Aug 2024 Top Applications of Foam Sheet Laboratory Machines in Material Testing and Development

In today's fast-paced world of material science and product innovation, foam sheet laboratory machines are integral tools that enable researchers, engineers, and product developers to explore new materials and optimize production processes.

17 Oct 2024

17 Oct 2024 Feininger's Foam Sheet Laboratory Machine: Revolutionizing XPS Foam Innovation

In the evolving landscape of material science, testing, and innovation, cutting-edge tools are essential for advancing research and development. Feininger, a leader in the production of XPS foam equipment, has taken a bold step forward with its Foam Sheet Laboratory Machine, designed specifically to address the needs of modern industries and academic institutions.

02 Apr 2025

02 Apr 2025 ETPU Beads Foam Production Line: Key Features and Innovations for Modern Foam Manufacturing

Central to the production of ETPU foam is the ETPU Beads Foam Production Line, a sophisticated system that integrates cutting-edge technology to ensure the highest levels of performance and quality.