COOPERATIVE PARTNER

Years Focused On Physical Foaming

Customers Worldwide

Countries Exported To All Over the World

Manufacturing Base

OUR HISTORY

Company

As demonstration enterprise appointed by World Environment-protection Organization, National High-tech Enterprise, Jiangsu Provincial Enterprise in Building Efficiency, Feininger bears Innovation through her developing.

The professional R&D center of Feininger has close co-operations with some academies and research institutions.

Founded in 2003, Feininger is a technology-based manufacturing company withfocus on R&D and industrialization of polymer lightweight technology.

Headquartered in Nanjing, China, Feininger is the National High-tech Enterprise, and thePresident of China XPS Industry Committee.

Feininger participated in the formulation of National Standards GB8624-2012GB/T10801.2-2018, and holds more than 30 authorized patents.

Feininger obtains ISO9001:2015,ISO14001:2015,ISO45001:2018 certifications.

Technology

Feininger XPS Backer Board: The Professional’s Choice for Superior Building Performance

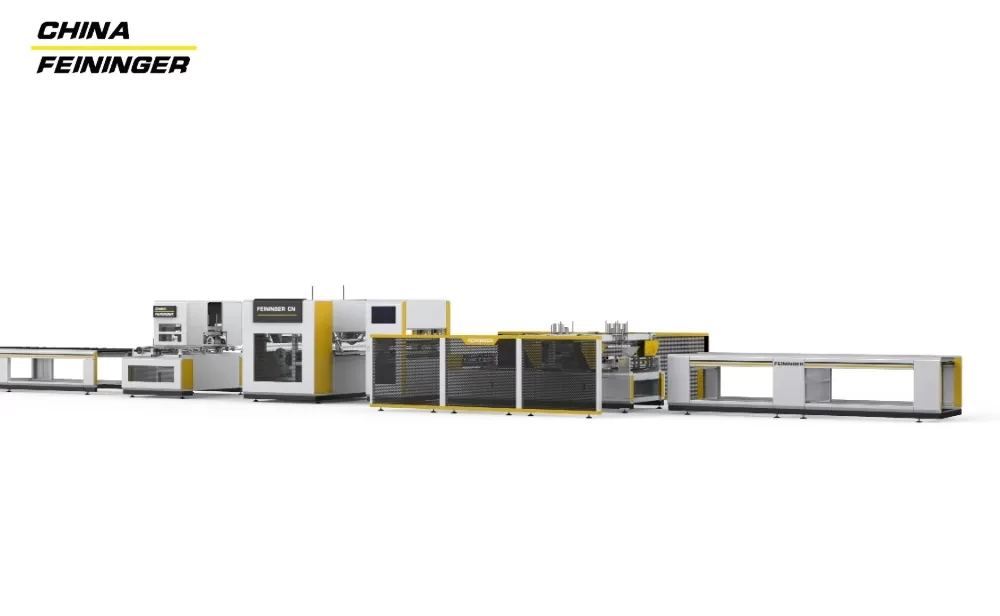

Advantages of Feininger Extrusion Production Equipment for Graphite EPS Particles

Outstanding production efficiency and stability High degree of automation Product quality Energy consumption and cost advantages Strong operation and adaptability

Process Flow for Producing Graphite EPS by Extrusion Method

The process flow of producing graphite EPS (expandable polystyrene) by extrusion is to melt and mix polystyrene-based raw materials through extrusion equipment, then cut into the required particles through high-pressure underwater pelletizing, and finally carry out sieving, coating and packaging to obtain products.