Technology

18

Jan . 2024Welcome to the world of efficient and high-quality cornice production with the XPS Cornice Production Line! If you're in the construction or interior design industry, you know that creating beautiful and intricate cornices can be a time-consuming and labor-intensive task. But fear not! With the help of Feininger, a leading XPS Cornice Production Line manufacturer in China, you can elevate your production process to new heights.

In this blog post, we'll explore how the XPS Cornice Production Line can revolutionize your manufacturing process. From its incredible benefits to its state-of-the-art features and components, we'll delve into everything you need to know about this cutting-edge technology. So let's dive in and discover how this innovative system can boost both efficiency and quality in cornice production!

The XPS Cornice Production Line offers numerous benefits that can greatly enhance the efficiency and quality of cornice production. One of the key advantages is its ability to automate the entire production process, reducing manual labor and increasing productivity. With this line, manufacturers can streamline their operations and produce a higher volume of cornices in less time.

Another benefit is the consistent quality achieved through using the XPS Cornice Production Line. The automated system ensures precise measurements and cuts, resulting in perfectly shaped cornices every time. This eliminates human error and guarantees a uniform finished product that meets customer expectations.

Furthermore, this production line enables customization options for cornices. Manufacturers can easily adjust settings to create different sizes, shapes, or patterns according to specific customer requirements. This flexibility allows for greater creativity and versatility in design while maintaining efficient production processes.

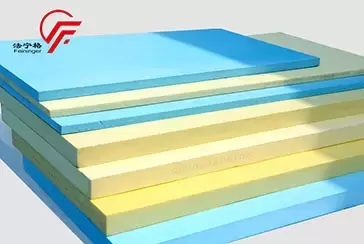

Additionally, by utilizing advanced technology and materials, such as high-quality XPS foam boards, the XPS Cornice Production Line helps to reduce waste during manufacturing. This not only saves costs but also contributes to sustainability efforts by minimizing environmental impact.

Investing in an XPS Cornice Production Line from China Feininger provides manufacturers with numerous benefits including increased productivity, consistent quality control, customization options, cost savings through waste reduction, and overall improvement in efficiency throughout their operations

The XPS Cornice Production Line is equipped with a range of advanced features and components that make it an efficient and high-quality solution for manufacturing cornices.

One key feature of the production line is its precise cutting mechanism, which ensures accurate dimensions and clean edges for every cornice produced. This helps to minimize wastage and improve overall efficiency.

Another important component of the XPS Cornice Production Line is the molding system. This system allows for the creation of intricate designs and patterns on the cornices, adding aesthetic value to the final products.

The production line also includes a heating element that enables quick and uniform melting of the XPS material. This ensures consistent quality across all cornices manufactured, without any variations in density or texture.

Additionally, the XPS Cornice Production Line incorporates an automated control panel, which simplifies operation and allows for easy monitoring of various parameters such as temperature, pressure, and speed. This not only saves time but also reduces human error during production.

Moreover, this production line is designed with durability in mind. The components are made from high-quality materials that can withstand continuous use in demanding manufacturing environments.

In conclusion, the diverse features and reliable components of the XPS Cornice Production Line contribute to its ability to boost efficiency and deliver top-notch quality. By investing in this innovative technology,manufacturers can streamline their operations and meet market demands effectively.With China Feininger being a leading manufacturer,the future impact of this production line looks promising

The XPS Cornice Production Line is a powerful tool that can greatly enhance efficiency and quality in the production of cornice products. But how exactly do you use this innovative machine to its full potential? Let's take a closer look at the step-by-step process.

First, ensure that all necessary materials are ready and easily accessible. This includes the XPS foam board, the cutting blades, the adhesive, and any decorative elements or coatings.

Next, set up the machine according to the specific requirements of your cornice design. Adjust the settings for thickness and width as needed.

Now it's time to load the XPS foam board onto the feeding system of the production line. Pay attention to proper alignment and positioning before starting.

Once everything is in place, activate the cutting mechanism on the machine. The blades will precisely shape and trim each section of foam board according to your desired cornice design.

After cutting, use appropriate adhesives or fasteners to assemble multiple sections if required by your design. Ensure secure bonding for maximum durability.

Apply any desired decorative elements or coatings to enhance aesthetics. Be creative with colors, textures, or patterns that align with your overall vision for your cornices.

By following these simple steps and utilizing all features provided by Feininger China’s XPS Cornice Production Line manufacturer, china feininger, you can streamline your manufacturing process while maintaining exceptional product quality. So don't hesitate – invest in this advanced technology today!

The XPS Cornice Production Line has proven to be a game-changer in the manufacturing industry, offering numerous benefits and features that boost efficiency and quality. As we have seen, this innovative production line streamlines the entire process of cornice production, saving time, reducing costs, and minimizing errors.

By utilizing advanced technology and automation, manufacturers can significantly improve their productivity while maintaining consistent quality standards. The precise cutting, shaping, and molding capabilities of the XPS Cornice Production Line ensure that every piece meets exact specifications.

Furthermore, with its user-friendly interface and intuitive controls, operators can easily set up and operate the production line without extensive training or expertise. This not only increases efficiency but also allows for flexibility in adapting to changing customer demands.

Looking ahead to the future impact of the XPS Cornice Production Line, it is clear that manufacturers will continue to benefit from its advantages. As more companies adopt this technology-driven solution as part of their operations, they will gain a competitive edge in terms of speed-to-market and product quality.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

12 Dec 2023

12 Dec 2023 Feininger won the top ten enterprises in China's polystyrene extrusion foam board industry

The XPS Special Committee of the China Plastics Association held the "2023 Annual Meeting and Re-election Conference of the XPS Special Committee of the China Plastics Association" at the Holiday Inn Guangzhou R&F Airport from December 6 to 8, 2023.

07 Oct 2023

07 Oct 2023 Mastering XPS Foam Board Production: A Comprehensive Guide

Welcome to the world of XPS Foam Board production! If you're looking to delve into this fascinating field or simply want to expand your knowledge, you've come to the right place. In this comprehensive guide, we will take you on a journey through the ins and outs of mastering XPS Foam Board production.

20 Jun 2025

20 Jun 2025 Enhancing Production Output with Automated XPS Foam Board Lines

As global demand for high-performance insulation materials surges, manufacturers are seeking faster, smarter, and more energy-efficient ways to produce XPS foam boards.