Technology

20

Jun . 2025As global demand for high-performance insulation materials surges, manufacturers are seeking faster, smarter, and more energy-efficient ways to produce XPS foam boards. This shift has made automated XPS foam board production lines a game-changing solution in the building materials industry. By integrating advanced automation technologies, these systems not only streamline production but also ensure consistent quality and lower operating costs.

In this blog, we explore how automated XPS production lines, especially those developed by industry leader Feininger, are transforming manufacturing workflows and maximizing output for insulation board producers worldwide.

Traditionally, XPS foam board production involved several labor-intensive steps—from feeding raw materials and controlling foaming agents, to managing cooling, cutting, and stacking. These processes often posed challenges such as material waste, inconsistent board quality, and limited production speeds.

Modern automated XPS lines, however, bring significant improvements by offering:

High-speed continuous extrusion and foaming

Precision in temperature and pressure control

Reduced labor dependency and human error

Real-time monitoring and fault detection

Automated feeding and cutting systems

The result? Significantly enhanced production efficiency, minimized downtime, and consistently high-quality boards.

As China’s first professional manufacturer specializing in XPS foam board equipment, Feininger has long been at the forefront of integrating automation into XPS production.

High Output & Energy Efficiency

Engineered for large-scale production, Feininger’s systems can deliver continuous output with lower energy consumption, allowing manufacturers to scale profitably.

CO₂ Foaming Technology

Environmentally friendly CO₂ is used as the blowing agent, aligning production with global green standards while improving insulation performance and cell uniformity.

Scientific Spiral Screw Structure

This ensures thorough mixing of materials with no dead corners—critical for achieving a consistent foam structure.

Automatic Feeding System

Keeps the production environment clean and organized, while reducing manual labor and feeding errors.

Precision Cooling Design

Guarantees uniform cooling, minimizing warping and defects in the final foam boards.

High Torque Gear Transmission

Boosts mechanical stability and extends the service life of the equipment while cutting down energy consumption.

Here's a breakdown of the direct benefits manufacturers can expect when upgrading to automated XPS foam board lines:

| Benefit | Impact on Production |

|---|---|

| Increased Output | Up to 30% higher daily capacity with optimized uptime |

| Lower Operating Costs | Less labor, reduced energy usage, minimal material waste |

| Better Product Consistency | Uniform density, thickness, and thermal performance |

| Faster Turnaround Time | Streamlined production enables quicker order delivery |

| Scalability | Easily adjust production levels based on demand |

As global markets place greater emphasis on sustainable construction and thermal efficiency, the need for fast, scalable, and clean production has never been greater. Manufacturers that embrace automation now will be well-positioned to meet future demand surges while maintaining operational efficiency.

Feininger’s cutting-edge technology, coupled with its free technical guidance and full-suite customization support, offers the ideal starting point for insulation producers aiming to lead—not just compete—in the XPS market.

Automation in XPS foam board manufacturing is no longer a luxury—it's a necessity for companies aiming to grow sustainably and stay ahead of competitors. With Feininger's automated XPS foam board production lines, manufacturers gain a reliable, efficient, and eco-conscious path to scale their business.

Learn more about Feininger’s production solutions at

https://www.china-feininger.com

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

24 May 2024

24 May 2024 The Ultimate Guide to Underfloor Heating Grooved Insulation Boards: Benefits and Applications

Underfloor heating systems are becoming increasingly popular due to their efficiency, comfort, and space-saving benefits. At the heart of an effective underfloor heating system is the insulation board.

21 Jun 2024

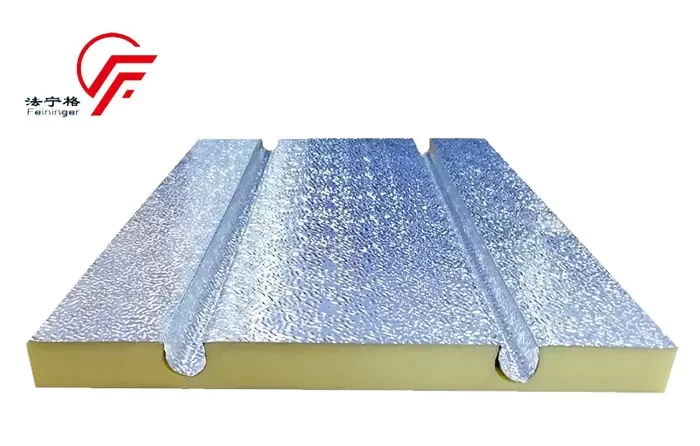

21 Jun 2024 The Future of Building Insulation: Trends and Innovations in XPS Foam Board with Aluminum Foil

As we move further into the 21st century, the demand for more efficient, sustainable building materials is on the rise. One of the standout products in this evolution is the XPS (Extruded Polystyrene) Foam Board with Aluminum Foil.

30 Oct 2023

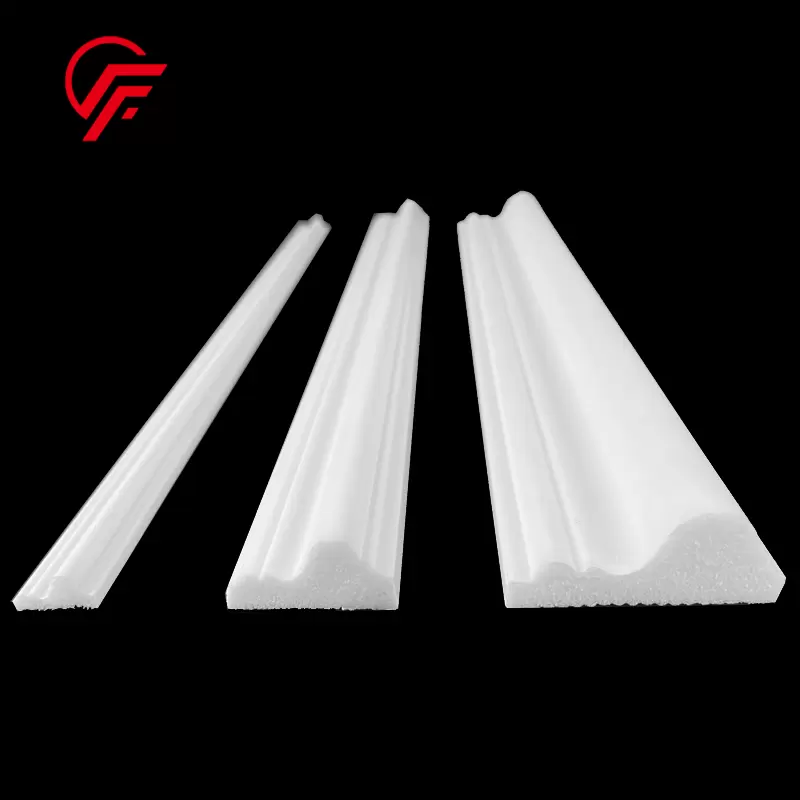

30 Oct 2023 How to Choose PS Decorative Lines?

Welcome to our blog post on how to choose the perfect PS Decorative Lines for your home or office! If you're looking to enhance the aesthetics of your space and add a touch of elegance, then PS Decorative Lines are the ideal solution. These decorative lines not only serve as beautiful accents but also provide functionality and durability.