Technology

02

Jul . 2025When it comes to exporting construction materials internationally, proper packaging and container loading are just as important as the product itself. For XPS Tile Backer Boards with a cement coating, this is especially true—both to preserve product integrity and to ensure a smooth delivery process. At Feininger, a leading manufacturer of XPS Tile Backer Boards in China, we take every step to guarantee safe and efficient container shipment.

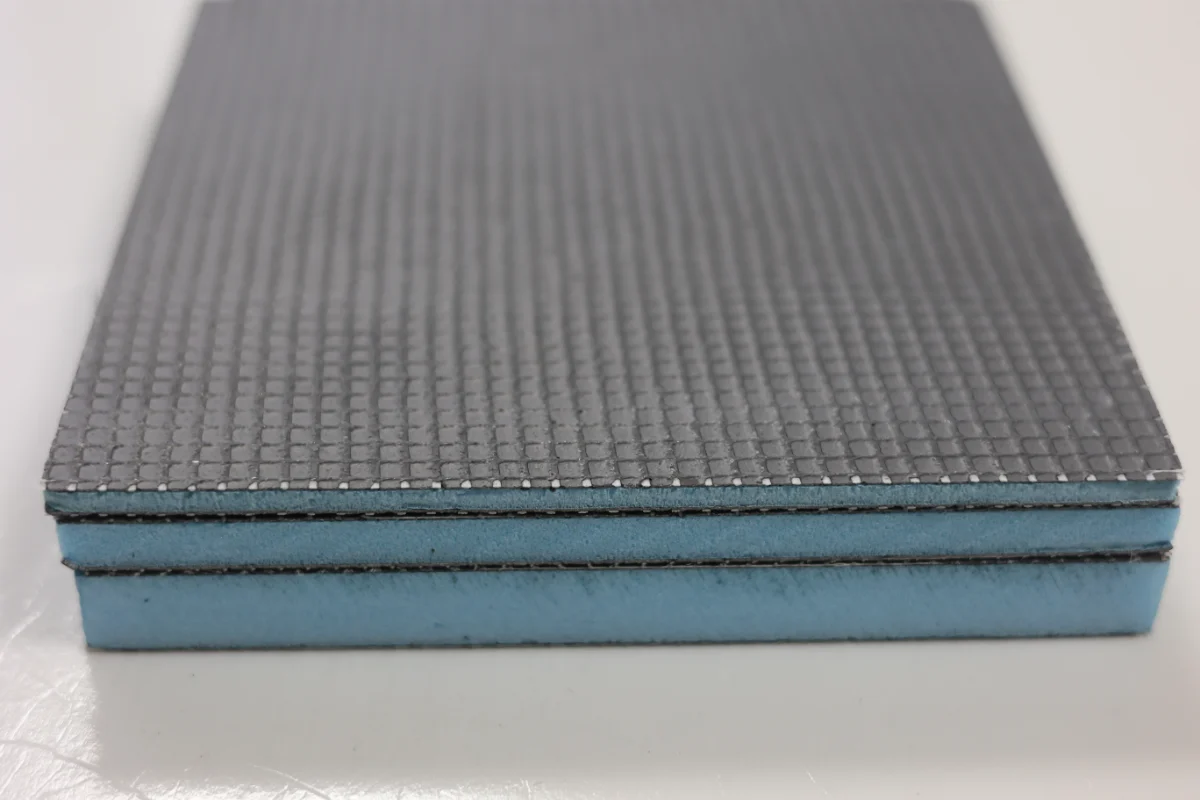

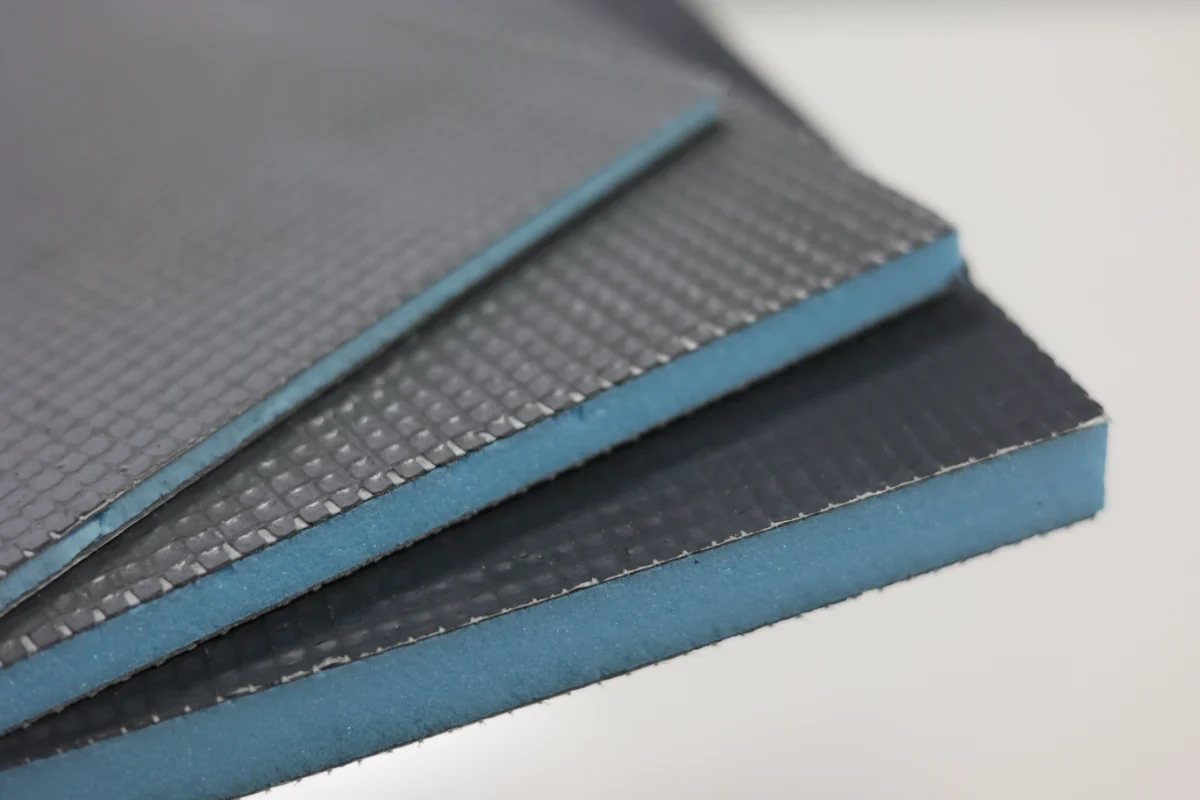

Cement-coated XPS Tile Backer Boards combine the lightweight and thermal insulation benefits of extruded polystyrene with the rigid durability of a cement surface. While the core XPS foam is resistant to moisture and compression, the cement layer is sensitive to impact during transport. That’s why careful stacking, protective wrapping, and optimized palletization are essential in international shipping.

Our factory follows a strict loading protocol to ensure your order arrives intact:

Palletized Packaging: Boards are neatly stacked on fumigation-free wooden pallets with protective corner guards and stretch film wrapping.

Optimized Container Use: We use 20-foot and 40-foot containers depending on order volume, maximizing space without overloading.

Shock-Absorbing Protection: Foam and cardboard layers are added between stacks to prevent surface chipping or edge damage.

Clear Labeling: Each pallet is labeled with product specifications, quantity, and handling instructions for easier unloading and inventory.

To provide transparency and peace of mind, Feininger documents the loading process with real-time photos. These images show how your XPS Tile Backer Boards are handled, loaded, and secured in the container. Clients can review the shipping condition before the vessel leaves port.

Whether you are a distributor, contractor, or project developer, receiving your building materials in perfect condition is critical. Feininger works with reputable freight forwarders and provides support for export documentation, customs clearance, and delivery coordination to your destination port or warehouse.

A successful shipment starts with strong packaging and professional logistics. With Feininger’s container loading experience and commitment to product quality, you can trust that your cement-coated XPS Tile Backer Boards will arrive ready for immediate installation.

Need a reliable XPS Tile Backer Board supplier? Contact Feininger today for product specs, price quotes, and export details.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

29 Sep 2024

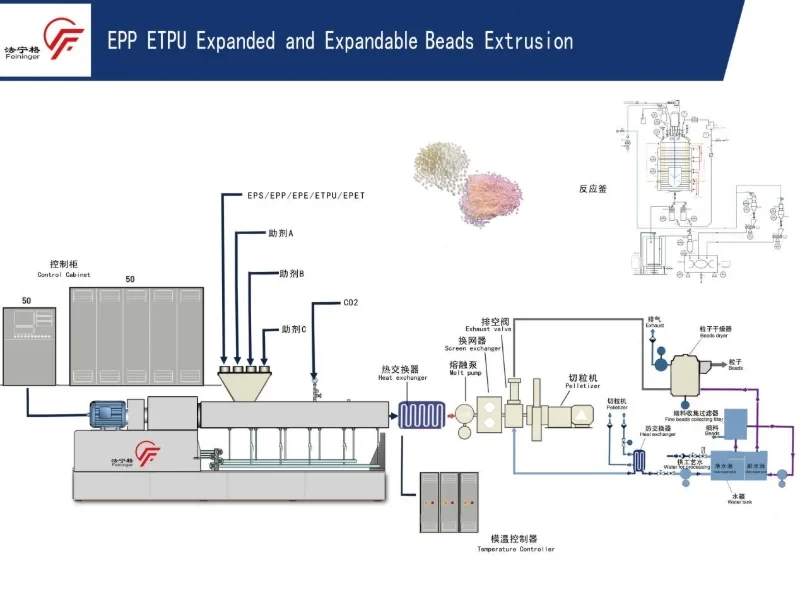

29 Sep 2024 Applications of ETPU Foam Particles in Automotive and Industrial Products

In recent years, ETPU (Expanded Thermoplastic Polyurethane) foam particles have garnered significant attention across various industries, particularly in automotive and industrial applications. Known in the industry as "magic particles," ETPU is celebrated for its impressive properties, including high resilience, lightweight composition, and versatility.

25 Apr 2025

25 Apr 2025 Exploring the Versatility of EPP Beads Foam Production Lines Across Different Industries

In recent years, Expanded Polypropylene (EPP) has emerged as one of the most innovative and environmentally friendly materials used in a variety of industrial applications. Known for its excellent properties, including lightweight, strong plasticity, and superior shock absorption, EPP is gaining traction across multiple industries.

08 Jul 2024

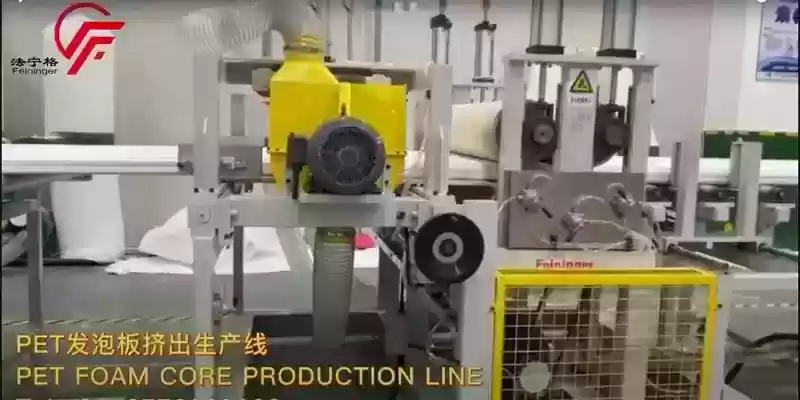

08 Jul 2024 Top 5 Benefits of Using a PET Foam Sheet Production Line in Your Business

In the competitive landscape of the plastics industry, adopting advanced production technologies can significantly enhance operational efficiency and product quality. One such innovation is the PET foam sheet production line, which offers numerous benefits for businesses.