Technology

25

Apr . 2025In recent years, Expanded Polypropylene (EPP) has emerged as one of the most innovative and environmentally friendly materials used in a variety of industrial applications. Known for its excellent properties, including lightweight, strong plasticity, and superior shock absorption, EPP is gaining traction across multiple industries. The evolution of EPP beads foam production lines, particularly through Feininger's EPP supercritical CO₂ primary foaming technology, has led to a significant leap forward in both material quality and production efficiency.

EPP, also referred to as Expanded Polypropylene, is a type of foam plastic material made from polypropylene. It is a high-crystallization polymer/gas composite that boasts exceptional performance and versatility. EPP foam is lightweight, durable, and provides excellent compression resistance, shock absorption, and thermal insulation, making it an ideal choice for various industries. Its unique characteristics allow it to maintain its structural integrity under stress, while offering significant protection against impact, vibration, and extreme temperatures.

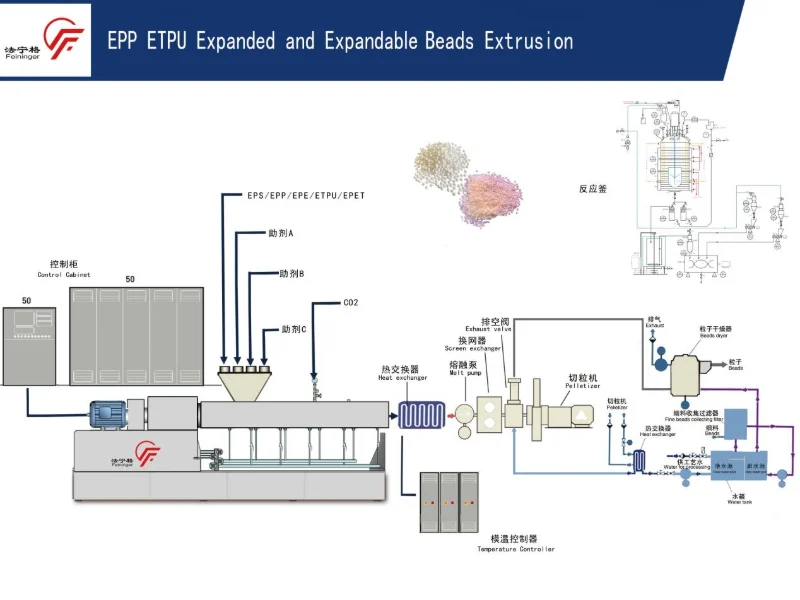

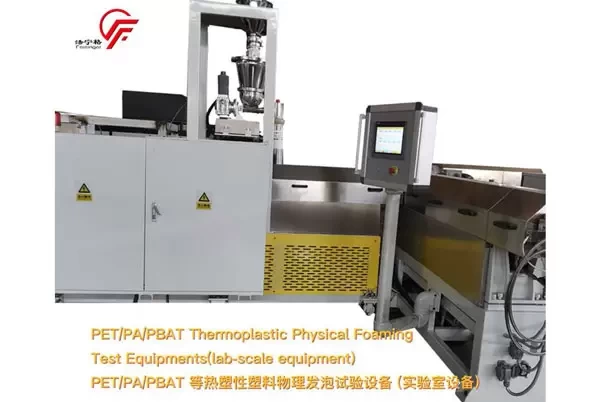

The breakthrough technology in EPP foam production comes from the introduction of Feininger’s EPP supercritical CO₂ primary foaming technology. This method involves the use of supercritical CO₂ as a foaming agent to create EPP beads. Supercritical CO₂ is a non-toxic, environmentally friendly substance that significantly improves the efficiency and quality of the foam production process. The results are lighter, more stable foam products with a reduced environmental footprint, which is becoming increasingly important in today’s eco-conscious market.

Feininger’s advanced foam production lines feature state-of-the-art equipment designed to maximize production speed, energy efficiency, and consistency in product quality. These systems can produce a variety of EPP bead sizes and densities, making them adaptable to specific industry requirements.

EPP’s wide range of applications is largely driven by its unique properties, which cater to the needs of several high-performance industries. Let's explore how different sectors are leveraging EPP beads foam production lines:

The automotive industry is one of the primary beneficiaries of EPP technology. EPP foam’s lightweight and shock-absorbing properties make it an ideal material for automobile interiors and exterior components. In particular, EPP is used for:

Impact protection in bumpers and side-impact beams.

Thermal insulation in car seats and door panels.

Soundproofing for improved cabin acoustics.

With the increasing demand for fuel-efficient vehicles, EPP’s lightweight characteristics help reduce the overall weight of vehicles, contributing to better fuel economy and improved performance.

In aerospace, reducing weight without sacrificing strength and safety is crucial. EPP foam meets this demand with its excellent shock-absorbing qualities and high strength-to-weight ratio, making it indispensable in applications such as:

Aircraft interior padding, where safety and comfort are top priorities.

Packaging materials for delicate equipment.

Noise reduction in aircraft cabins.

With Feininger’s EPP beads foam production lines, the aviation industry can now produce custom-sized EPP foam components with a high degree of precision and reliability.

EPP foam is highly effective in protecting sensitive electronic devices during transport. Its shock resistance ensures that electronic goods remain safe and intact, even in the most demanding shipping environments. Industries such as consumer electronics, medical devices, and industrial equipment rely on EPP foam for:

Protective packaging for smartphones, laptops, and other fragile electronics.

Thermal insulation in batteries and electrical enclosures.

Vibration damping for sensitive machinery and components.

The versatility of EPP beads foam allows it to be molded into a variety of shapes and sizes, enhancing the protection and longevity of valuable electronic goods.

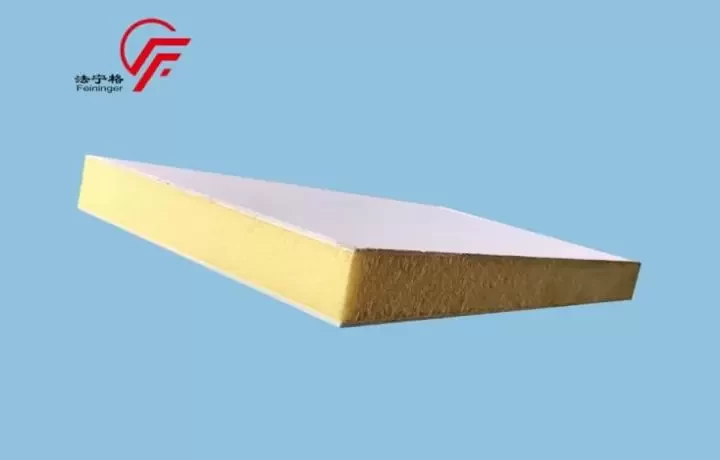

EPP’s thermal insulation properties are indispensable in the construction industry. Its low thermal conductivity makes it an ideal material for insulating walls, roofs, and floors in buildings. Moreover, EPP is lightweight, making it easy to handle and install in both residential and commercial projects. Some common applications in construction include:

Insulated panels for buildings, improving energy efficiency.

Thermal insulation in pipes and tanks.

Floatation devices for marine construction projects.

EPP beads foam production lines, especially those utilizing Feininger’s advanced foaming technology, ensure that these applications are not only highly functional but also environmentally sustainable.

The sports equipment industry uses EPP for impact protection in various products. The foam’s ability to absorb shocks makes it ideal for safety gear such as:

Helmet padding.

Sports footwear for shock-absorption and comfort.

Protective padding in sports training equipment.

By customizing the density and size of the foam beads, manufacturers can produce high-quality, durable protective gear for athletes, enhancing both performance and safety.

Feininger’s EPP beads foam production lines stand out in the market for several reasons:

Cutting-edge Technology: The introduction of supercritical CO₂ for foaming ensures a high-quality, environmentally friendly product.

Customization: Feininger’s production lines are designed to create a range of EPP bead sizes and densities tailored to specific industry needs.

Energy Efficiency: With modular designs, these production lines reduce energy consumption and improve cost-efficiency for manufacturers.

Environmental Benefits: The use of supercritical CO₂ significantly lowers the environmental impact of foam production, aligning with global sustainability goals.

High Performance: Feininger’s production lines are built for speed, precision, and durability, ensuring consistent results with minimal downtime.

The versatility of EPP beads foam production lines has transformed industries ranging from automotive to aerospace, electronics, construction, and beyond. With Feininger’s innovative supercritical CO₂ primary foaming technology, the production of high-quality EPP foam has become more efficient, sustainable, and customizable. As the demand for eco-friendly, lightweight, and durable materials continues to grow, EPP will undoubtedly play a central role in shaping the future of various industries.

By embracing these technological advancements, businesses can maximize the potential of EPP foam to improve product performance, reduce environmental impact, and meet the evolving needs of the global market.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

21 Aug 2024

21 Aug 2024 Innovative Features to Look for in a Foam Sheet Laboratory Machine

In the world of materials science and product development, foam sheet laboratory machines play a critical role in research, testing, and small-scale production.

16 Nov 2023

16 Nov 2023 Let's Get To Know Feininger

Feininger is the first professional manufacturer of XPS Extrusion Line and XPS Foam Board here in China. At the same time we are the unique enterprise specializing in XPS Foam as well as developing, manufacturing and selling of XPS equipment.

18 Feb 2025

18 Feb 2025 Step-by-Step Guide to Setting Up an XPS Foam Board Production Line

The demand for high-quality, energy-efficient insulation materials has grown significantly in recent years, and one of the most popular choices for insulation is XPS foam board.