Technology

29

Sep . 2024In recent years, ETPU (Expanded Thermoplastic Polyurethane) foam particles have garnered significant attention across various industries, particularly in automotive and industrial applications. Known in the industry as "magic particles," ETPU is celebrated for its impressive properties, including high resilience, lightweight composition, and versatility. This blog post will explore the diverse applications of ETPU foam particles and how they are transforming automotive and industrial products.

ETPU foam particles are a new type of polymer material made up of lightweight TPU foam pellets. With exceptional elasticity and durability, ETPU stands out as one of the most elastic foam materials available on the market today. It is specifically designed to withstand rigorous use while maintaining its shape and performance. In addition to being a premium sole material for footwear, ETPU has expanded its reach into numerous sectors, including sporting goods, leisure and fitness equipment, and furniture.

High Resilience: ETPU foam particles provide exceptional bounce-back properties, making them ideal for applications requiring shock absorption and comfort.

Lightweight: The lightweight nature of ETPU reduces overall product weight, contributing to energy efficiency, especially in automotive applications where fuel consumption is a concern.

Durability: ETPU foam is resistant to wear and tear, ensuring that products maintain their integrity over time, even in demanding environments.

Anti-Yellowing Agents: The use of anti-yellowing agents in high-quality ETPU products helps maintain the aesthetic appeal, particularly for white and light-colored items, ensuring longevity in appearance.

ETPU foam is increasingly used in automotive interiors, including seat cushions, headrests, and armrests. Its high resilience and comfort properties make it an excellent choice for enhancing passenger experience. ETPU’s lightweight nature also contributes to overall vehicle weight reduction, improving fuel efficiency.

ETPU foam particles offer excellent sound-dampening capabilities, making them ideal for noise reduction in vehicles. By integrating ETPU into door panels, dashboards, and other interior components, manufacturers can create a quieter and more pleasant driving experience.

In safety applications, ETPU foam can be used in protective padding for various automotive components. Its energy-absorbing properties help mitigate impact forces during collisions, contributing to passenger safety.

The cushioning properties of ETPU make it an excellent choice for protective packaging materials. Its lightweight and durable characteristics help safeguard products during shipping, reducing the risk of damage and ensuring products arrive in optimal condition.

In industrial settings, ETPU foam is used in safety footwear, providing comfort and support for workers who are on their feet for extended periods. The high resilience and shock absorption capabilities of ETPU help reduce fatigue and enhance overall productivity.

The versatility of ETPU has led to its use in various sporting goods, including protective gear and equipment. Its ability to absorb shocks and provide comfort makes it an ideal material for items like knee pads, helmets, and athletic footwear.

At China Feininger, we not only provide high-quality ETPU foam particles but also offer an advanced ETPU production line. Our extrusion ETPU production line employs mature processes and high equipment stability to ensure consistent product quality.

Supercritical CO2 Fluid Kettle Pressure Foaming: This innovative method effectively addresses the challenges of hydrolysis and yellowing in polyester ETPU during the application phase.

Pressure Compensation Technology: This new approach enhances the foaming process, leading to improved product characteristics and performance.

ETPU foam particles are revolutionizing the automotive and industrial sectors with their unique properties and diverse applications. From enhancing comfort in vehicle interiors to providing protection in packaging and sporting goods, ETPU is proving to be an invaluable material. With China Feininger’s commitment to quality and innovation, we are poised to lead the way in delivering exceptional ETPU solutions tailored to meet the evolving needs of the industry. Embrace the future of materials with ETPU foam particles and discover the myriad benefits they can bring to your products.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

10 Jul 2024

10 Jul 2024 Common Challenges in PET Foam Sheet Production and How to Overcome Them

Producing high-quality PET foam sheets is an intricate process that involves multiple stages, from raw material preparation to extrusion and foaming. Despite the advanced technology and machinery used, manufacturers often face several challenges.

05 Mar 2025

05 Mar 2025 How PET Foam Sheet Production Lines Improve Efficiency and Reduce Waste

China Feininger, a leading manufacturer in XPS and PET foam extrusion technology, has developed high-performance PET foam sheet production lines that not only enhance manufacturing efficiency but also significantly reduce environmental impact.

07 Mar 2024

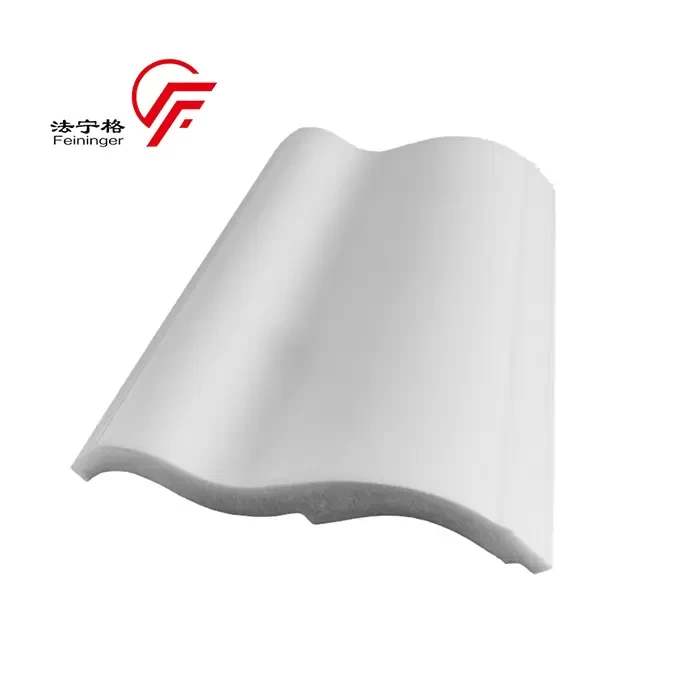

07 Mar 2024 XPS Decorative Moulding: Enhance Interiors with Style

Are you seeking to elevate your space with a touch of elegance and sophistication? Look no further than XPS decorative moulding. Transforming ordinary rooms into extraordinary spaces, XPS decorative moulding offers a seamless way to add charm and character to your home or office.