Technology

10

Jul . 2025Effective insulation is an important aspect of flooring in any cold storage facility. It helps maintain the correct internal temperature and reduces energy use. In the case of refrigerated cold storage, it is necessary to consider the reversal of the usual flow of heat and moisture from the inside out. Unlike conventional building structures, heat diffuses through floors and enclosures, flowing from the wet subsoil and external environment to the colder, drier interior of the refrigerated cold storage area.

In addition to important factors such as thermal efficiency and moisture resistance, the insulation of extruded panels in refrigerated cold storage needs to have sufficient compressive strength characteristics. It must be able to withstand the loads of other flooring materials, as well as the dynamic and static weight of the activities of goods and people stored in refrigerated cold storage facilities.

By measuring the compressive behavior of a material, such as an insulating material, its ability to resist loads applied to it can be assessed and determined. The test method for insulating materials involves placing the sample between two plates of the test instrument and applying varying degrees of force. Depending on the test method and standard, the compression properties of the insulation material will also vary.

In one case, it can refer to compressing an insulator into a load of 10% of its thickness, resulting in relative deformation relative to the thickness of the original sample. Alternatively, it can refer to the load at "yield", which is the point at which the insulating material can be described as having failed before compressing 10%.

The insulation material will never be used in situations where compression is possible by 10%. The consequences of this large movement are unbearable for any cold storage extruded panel material. Assessing the compressive properties of the floor and specifying the correct insulation material is critical to the safety and proper functioning of the refrigerated cold storage structure.

Insulated concrete slabs are a common requirement for refrigerated cold storage facilities. Therefore, the insulation material used for extruded panels in refrigerated cold storage must be able to withstand heavy loads. This includes structural loads from the floor itself, in addition to stored cargo and power loads from pedestrians and heavy vehicles driving on the floor.

Another important consideration when specifying the insulation of extruded panels in a cold storage freezer is to consider compression creep. Long loading produces progressive compression, affecting different materials in different ways. Therefore, the long-term effects of the load require a different measurement method – compression creep. The static weight of the stored goods is more likely to be the cause of compression creep.

Unfortunately, many insulation material manufacturers do not test for compression creep because it requires a test cycle of 122 to 608 days, depending on the simulation period - 10, 25 or 50 years. Some manufacturers claim that the compression creep changes to "compression strength at 2% compression" or similar, as the total compression proven is usually around 2%.

Cold storage extruded panels provide the maximum range of compressive strength and are one of the few insulating products where manufacturers invest time in testing and declaring compression creep. The evenly distributed closed holes in the extruded panels in the cold storage give them excellent compressive strength characteristics. This makes it a reliable and long-lasting solution when used on extruded panels in refrigerated cold storage that must withstand heavy loads.

In addition to its high compressive strength, refrigerated cold storage extruded plastic panels have other characteristics that make them ideal for use in refrigerated cold storage. It has a high, stable, predictable thermal conductivity, is highly moisture resistant, is very durable, and has a long service life.

Feininger's range of extruded panels for refrigerated cold storage is available in a variety of sizes, thicknesses and compressive strengths to meet the requirements of any cold storage extruded panel specification. Feninger extruded panels are ideal for chilled and cold-pultruded panels because they have a basic compressive strength of 300 kPa and a basic compressive strength of 500 kPa, so they can withstand higher floor loads in refrigerated cold storage facilities.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

07 Aug 2024

07 Aug 2024 Enhancing Efficiency: The Latest Innovations in PET Foam Core Production

The demand for lightweight, durable, and versatile materials has grown significantly in industries such as aerospace, automotive, and construction. PET foam cores have emerged as a popular choice due to their excellent mechanical properties and sustainability.

21 Jun 2024

21 Jun 2024 The Future of Building Insulation: Trends and Innovations in XPS Foam Board with Aluminum Foil

As we move further into the 21st century, the demand for more efficient, sustainable building materials is on the rise. One of the standout products in this evolution is the XPS (Extruded Polystyrene) Foam Board with Aluminum Foil.

29 Apr 2025

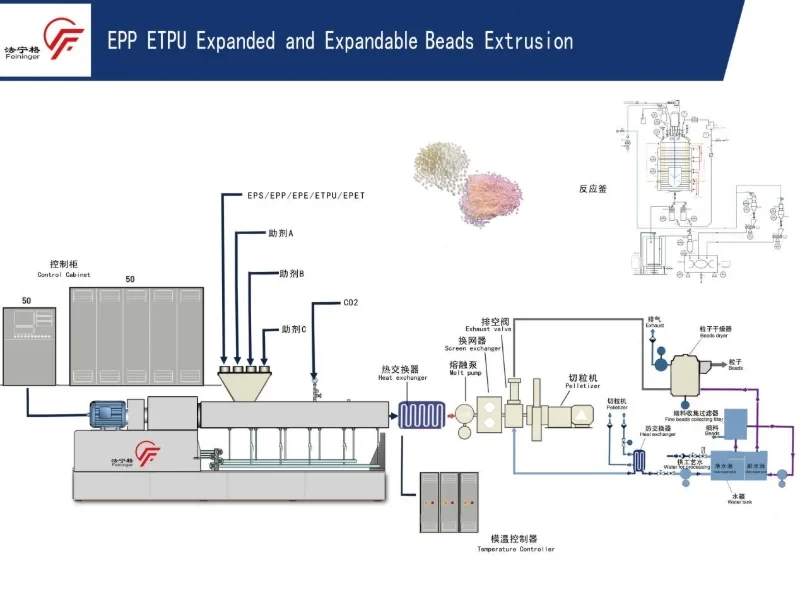

29 Apr 2025 EPP Beads Foam Production Line: Key Benefits for Lightweight and Durable Foam Products

In the field of advanced polymer foam manufacturing, Expanded Polypropylene (EPP) has emerged as a star material for delivering lightweight, durable, and eco-friendly foam solutions across industries.