Technology

10

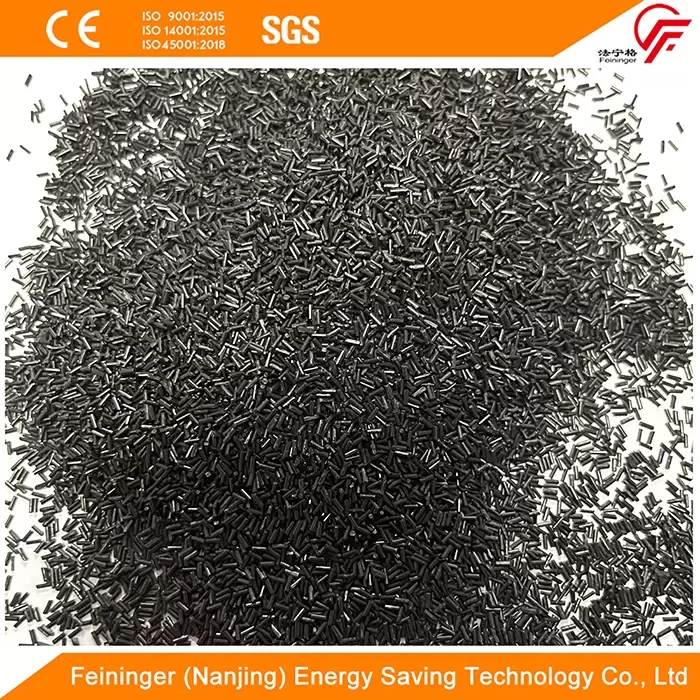

Sep . 2024Expanded Polystyrene (EPS) has long been recognized as an effective insulation material. However, EPS Graphite Particles take the insulation game to the next level. By incorporating graphite into the structure of traditional EPS, this advanced material offers improved insulation properties, making it a go-to solution for energy-efficient buildings and industrial applications.

EPS, short for Expanded Polystyrene, is a rigid foam plastic formed by heating polystyrene resin with a foaming agent. The result is a lightweight, hard-foam material made up of evenly distributed closed-cell structures. This unique composition is responsible for EPS’s excellent insulation properties, low water absorption, and lightweight characteristics. When graphite is added to EPS, it creates EPS Graphite Particles, significantly boosting the material's ability to reflect heat and enhance thermal insulation.

Enhanced Thermal Efficiency

The introduction of graphite particles into EPS boosts the material’s insulation capabilities by reflecting radiant heat. This means that EPS Graphite Particles offer superior thermal performance compared to regular EPS, making it ideal for construction projects aiming for energy efficiency. Buildings using this insulation can significantly reduce heating and cooling costs.

Low Water Absorption

Similar to standard EPS, EPS Graphite Particles maintain a low water absorption rate. This makes them suitable for environments where moisture might be a concern. The closed-cell structure ensures that water and vapor penetration is minimized, preserving the integrity and insulating performance of the material over time.

Lightweight but Durable

One of the major advantages of EPS Graphite Particles is that, despite their enhanced insulation properties, they remain lightweight. This reduces the overall load on the structure where they are installed, while still providing durability and strength, making transportation and installation more cost-effective.

Versatile Applications

EPS Graphite Particles are commonly used in applications where enhanced insulation is critical, such as in construction for thermal insulation panels, industrial cooling systems, and even packaging materials. Their versatility extends to different shapes and sizes, thanks to custom molding capabilities.

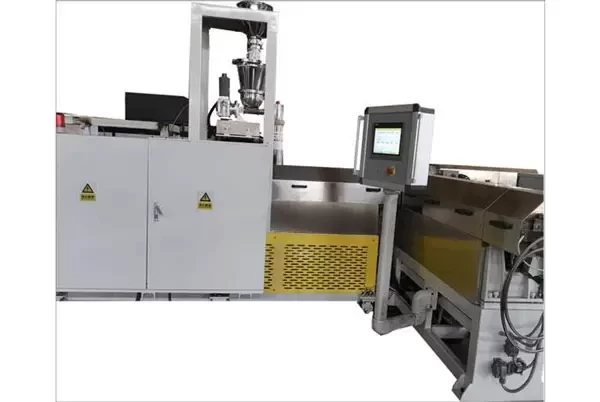

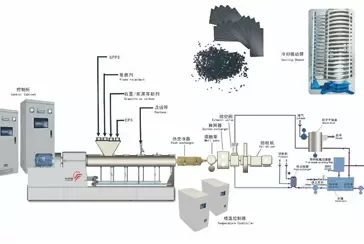

China Feininger, a leader in the EPS industry, not only provides EPS Graphite Particles but also specializes in producing EPS Beads Foam Extrusion Lines. This dual capability ensures that customers receive high-quality materials for their insulation needs, as well as the equipment necessary for producing EPS products tailored to specific applications. With a commitment to innovation and quality, China Feininger helps clients achieve their energy-saving goals through advanced EPS technology.

As the demand for energy-efficient and sustainable construction materials rises, EPS Graphite Particles offer a compelling solution for enhanced insulation. With improved thermal performance, low water absorption, and lightweight characteristics, this material is a smart choice for a range of insulation applications. China Feininger's expertise in providing high-quality EPS materials and extrusion lines ensures that customers receive cutting-edge solutions for their insulation needs.

By adopting EPS Graphite Particles, businesses and builders can not only meet current energy-efficiency standards but also future-proof their projects with superior insulation performance.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

29 Oct 2024

29 Oct 2024 How Feininger's Foam Sheet Laboratory Machine Enhances XPS Foam Research

In the rapidly evolving field of materials science, the need for advanced testing and research equipment is paramount. For researchers focused on extruded polystyrene (XPS) foam, the Foam Sheet Laboratory Machine from China Feininger stands out as an invaluable tool.

11 Apr 2025

11 Apr 2025 Advanced Technology in EPS Beads Foam Production: A Look at Feininger’s Cutting-Edge Solutions

In the world of foam production, particularly EPS (Expanded Polystyrene), technology plays a crucial role in determining product quality, operational efficiency, and overall cost-effectiveness.

18 Sep 2024

18 Sep 2024 Maximizing Thermal Performance with EPS Graphite Particle Technology

In today's fast-paced world, effective thermal management is crucial for a wide range of applications, from construction to electronics. One of the most innovative solutions making waves in the industry is the use of EPS (Expanded Polystyrene) Graphite Particle technology.