Technology

18

Sep . 2024In today's fast-paced world, effective thermal management is crucial for a wide range of applications, from construction to electronics. One of the most innovative solutions making waves in the industry is the use of EPS (Expanded Polystyrene) Graphite Particle technology. This approach not only enhances thermal performance but also addresses environmental concerns with its lightweight and efficient characteristics.

EPS, or Expanded Polystyrene, is a rigid foam material created by adding a foaming agent to polystyrene resin. When heated, the resin softens and expands, forming a closed-cell structure that boasts numerous advantages. The unique configuration of EPS contributes to its low water absorption rates, excellent insulation properties, and lightweight nature, making it a favored choice in various sectors.

Incorporating graphite into EPS significantly amplifies its thermal performance. Graphite is renowned for its exceptional thermal conductivity, which, when combined with EPS, creates a product that not only insulates effectively but also manages heat more efficiently. This synergy allows for:

Enhanced Insulation: The closed-cell structure of EPS, combined with graphite's thermal properties, results in superior insulation capabilities, ideal for applications in construction and packaging.

Weight Reduction: EPS Graphite Particles maintain a lightweight profile, which is crucial for reducing transportation costs and facilitating easier handling in various applications.

Durability: The robust nature of EPS combined with graphite’s resilience ensures a longer lifespan, reducing the need for frequent replacements and further minimizing environmental impact.

At China Feininger, we leverage advanced technology to produce EPS Graphite Particles. Our underwater extrusion process is designed for optimal performance, utilizing high water pressure and meticulously controlled temperatures. This precision ensures that the die does not clog, preventing premature foam formation within the pipeline.

Following extrusion, our innovative centrifugal drying and vibration cooling techniques ensure that the beads are properly processed and cooled. The self-designed vibration mechanism facilitates efficient production, guaranteeing that our customers receive high-quality products without compromising on output.

China Feininger prides itself on providing not only EPS Graphite Particles but also the EPS Beads Foam Extrusion Line. Our extensive experience in graphite EPS production translates into operational stability and increased profitability for our clients. Moreover, we offer free technical training to ensure that our customers can operate our equipment with ease, reducing downtime and operational costs.

Incorporating EPS Graphite Particle technology into your products can significantly enhance thermal performance while maintaining an eco-friendly profile. With China Feininger’s expertise and commitment to quality, you can trust that our solutions will not only meet but exceed your expectations. Experience the future of thermal management with EPS Graphite technology—where performance meets sustainability.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

23 Jul 2024

23 Jul 2024 Exploring the Benefits of TPU Underwater Pelletizers in Polymer Processing

In the dynamic world of polymer processing, efficiency and quality are paramount. Thermoplastic polyurethane (TPU) underwater pelletizers have emerged as essential tools in this industry, offering numerous advantages that enhance both production and product performance.

28 May 2025

28 May 2025 Common Mistakes to Avoid When Operating a PS Skirting Production Line

In the world of interior and exterior decoration, PS skirting boards have become a preferred choice due to their lightweight nature, aesthetic versatility, and ease of installation.

22 Nov 2024

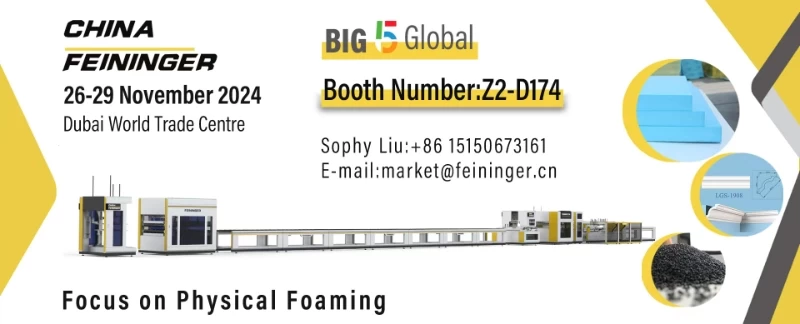

22 Nov 2024 China Feininger at BIG 5 Global 2024: Showcasing Cutting-Edge XPS Foam Board Technology

China Feininger, a leading manufacturer in the field of extrusion lines for XPS (Extruded Polystyrene) foam boards, is set to attend the highly anticipated BIG 5 Global event in Dubai.