Technology

09

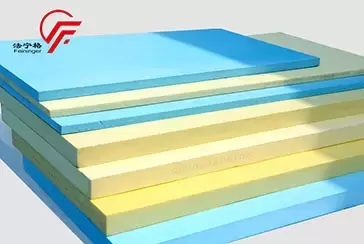

May . 2025In the realm of architectural decoration, XPS (extruded polystyrene) cornices have become a popular choice for interior and exterior molding due to their lightweight structure, durability, and thermal insulation properties. However, the efficiency and quality of XPS cornice production rely heavily on the technology and precision of the production line. This is where the Feininger XPS Cornice Production Line stands out, offering manufacturers an unparalleled combination of speed, quality, and energy efficiency.

In today's competitive construction and decorative materials market, production efficiency is a key differentiator. The ability to manufacture high-quality cornice profiles at scale, while minimizing operational costs and material waste, directly translates to better profit margins and faster market responsiveness.

Feininger, a leading expert in foam extrusion machinery, has developed a high-performance XPS cornice production line specifically designed to meet these demands.

Feininger’s system utilizes a 100% CO₂ foaming process, making it environmentally friendly while also improving the cell structure and consistency of the final cornice profiles. The temperature control of the foaming agent injection systems and integrated heat exchanger ensures optimal expansion, density control, and excellent surface quality. This scientific configuration leads to fewer defects, lower material waste, and reduced post-processing.

The feed system in the Feininger XPS Cornice Production Line is engineered for continuous, stable, and high-speed operation. This reduces downtime, minimizes maintenance intervals, and supports consistent throughput, allowing manufacturers to meet high-volume production demands without compromising on quality.

Unlike many competing systems that suffer from inconsistent density, Feininger has achieved a balance that produces low-density cornices with high compressive strength. This makes the profiles not only easier to handle and install but also highly resistant to deformation and wear—important for both transportation and long-term usage.

Energy consumption is a critical cost factor in extrusion manufacturing. Feininger’s system is built with a scientific gearbox configuration and low-power motors, offering exceptional energy efficiency without compromising output speed. This translates into lower electricity bills and a smaller carbon footprint—two significant advantages for manufacturers focused on sustainability and cost control.

With decades of experience in extruded profile production, Feininger doesn’t just sell machines; they offer a comprehensive solution. Customers benefit from free training, technical support, and customized guidance to avoid common mistakes and quickly get up to speed. This hands-on support ensures a shorter learning curve and smoother ramp-up for production teams.

Reliable Mold Design: The molding systems used in the Feininger XPS cornice line are precision-machined to guarantee dimensional accuracy and smooth surface finishes.

Integrated Quality Control: In-line monitoring and calibration systems help maintain consistency across batches and reduce rework.

Customizable Configurations: The line can be adjusted for different profile shapes and dimensions, giving manufacturers the flexibility to meet evolving market demands.

Feininger is not just a machinery supplier; it is a trusted technical partner in foam extrusion. Their dedication to innovation, performance, and client success is evident in every component of their XPS cornice production line.

Whether you’re expanding your production capacity or upgrading from traditional systems, choosing Feininger’s high-performance XPS Cornice Production Line is a strategic move that ensures higher productivity, consistent quality, and long-term cost efficiency.

Final Thoughts

As the demand for decorative yet functional building materials grows, manufacturers must equip themselves with advanced technologies to stay ahead. With its efficient design, energy-saving systems, and robust support, Feininger’s XPS Cornice Production Line empowers manufacturers to maximize output, reduce waste, and enhance profitability—all while delivering top-tier cornice products that meet modern aesthetic and structural standards.

Interested in transforming your production capabilities? Contact Feininger today to learn more about our XPS Cornice Production Line and expert support services.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

07 Oct 2023

07 Oct 2023 Mastering XPS Foam Board Production: A Comprehensive Guide

Welcome to the world of XPS Foam Board production! If you're looking to delve into this fascinating field or simply want to expand your knowledge, you've come to the right place. In this comprehensive guide, we will take you on a journey through the ins and outs of mastering XPS Foam Board production.

05 Nov 2024

05 Nov 2024 From Lab to Industry: Applications of the Beads Foam Experiment Machine

In the world of material science and manufacturing, innovation is driven by advanced research and testing technologies. One such technological marvel is the Beads Foam Experiment Machine, particularly designed for testing thermoplastic materials like PBAT, PA, and PET.

05 Sep 2024

05 Sep 2024 Streamlining Operations with the Latest XPS Cornice Production Line Innovations

In today's competitive manufacturing landscape, businesses are always seeking ways to streamline operations, reduce costs, and enhance productivity.