Technology

22

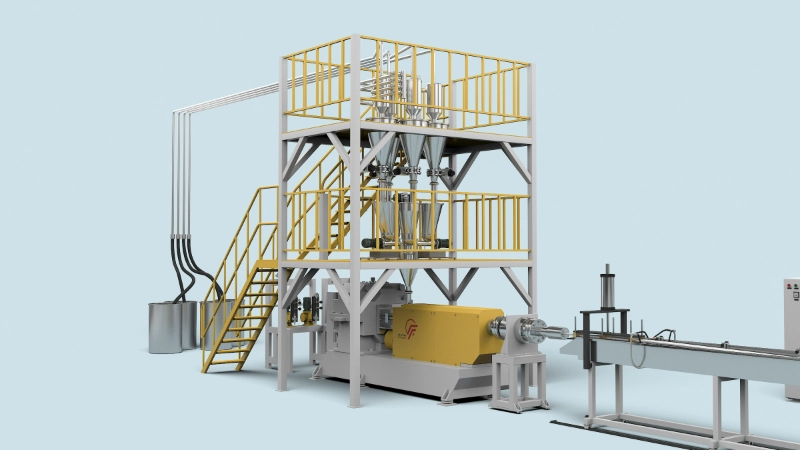

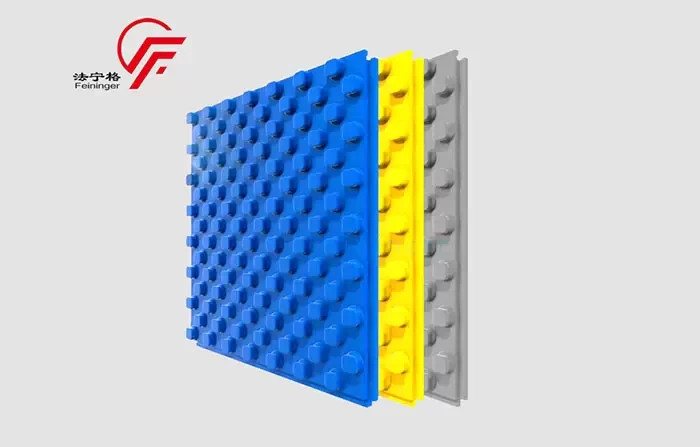

May . 2025In the world of modern interior decoration and construction, PS (Polystyrene) skirting is becoming an increasingly popular material thanks to its lightweight, durable, and aesthetically pleasing properties. Behind the scenes of these well-finished products lies an advanced and precisely engineered system: the PS Skirting Production Line. In this blog post, we will explore the key components and processes that drive the production of high-quality PS skirting boards—particularly through the innovative machinery provided by Feininger.

Unlike traditional chemical foaming systems, Feininger PS skirting line production machines utilize supercritical CO₂ physical foaming, significantly reducing the environmental footprint of production. This technique not only lowers the product density but also avoids the use of harmful chemical blowing agents—making the final products safer, more eco-friendly, and in line with global sustainability standards.

Let's take a step-by-step look at how Feininger's PS skirting production line works, from raw material input to final packaging.

The process starts by adding raw materials in specific proportions into a high-speed mixer. These materials are thoroughly blended and homogenized to create a consistent base for extrusion.

The mixed material is transferred to a feeder bin, where it is measured and delivered to the main extruder via a quantitative feeder. This ensures that the exact amount of material required is consistently supplied.

Inside the main extruder, a high-temperature screw conveys the raw materials to a heat exchanger. This component ensures uniform thermal distribution, which is critical for optimal foaming and material properties.

One of the defining technologies of Feininger’s system is the precise injection of supercritical CO₂ foaming agent. This step takes place just before the material exits the die. It’s a clean, physical foaming process that reduces material density and enhances environmental safety.

Once extruded, the foamed material is pushed through a mould and a two-stage shaping jacket. This cools and forms the high-temperature product into its desired skirting board profile.

After initial shaping, the material passes through a water cooling channel, further stabilizing the structure and ensuring dimensional accuracy.

The cooled PS skirting boards are then pulled forward by a tractor (haul-off unit) and precisely cut to length using a fixed-length cutting system.

The finished skirting boards are inspected, bundled, and packaged for distribution—ready to serve as premium decorative solutions for homes and commercial buildings alike.

✅ Eco-Friendly Manufacturing: Supercritical CO₂ foaming avoids chemical emissions.

✅ Low Product Density: Reduces transportation costs and eases installation.

✅ High Efficiency: Automated steps ensure consistent output and minimal human error.

✅ Customizable: Adjust mixing ratios, dimensions, and profiles based on market demands.

✅ Stable and Reliable Equipment: Built for continuous operation with low energy consumption.

The PS skirting production line is more than a series of machines—it’s an integrated system that transforms raw polystyrene into functional, stylish, and sustainable decorative products. Feininger’s state-of-the-art production line, with its advanced CO₂ foaming technology, offers manufacturers a competitive edge by combining quality, eco-consciousness, and production efficiency.

Whether you are expanding your manufacturing capabilities or entering the PS skirting market, Feininger’s turnkey solutions ensure you’re equipped with the best tools for success.

Interested in upgrading to a high-performance PS Skirting Production Line?

Contact Feininger today for detailed specifications, pricing, and technical support.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

28 May 2025

28 May 2025 Common Mistakes to Avoid When Operating a PS Skirting Production Line

In the world of interior and exterior decoration, PS skirting boards have become a preferred choice due to their lightweight nature, aesthetic versatility, and ease of installation.

16 Aug 2023

16 Aug 2023 Difference Between Physical Foaming and Chemical Foaming

Foam, with its unique structure and versatile properties, can be crafted using various methodologies, primarily bifurcated into two dominant techniques: physical and chemical foaming. Though both aim to introduce air bubbles or pockets into materials, the mechanisms and intricacies behind each process are markedly different.

16 May 2024

16 May 2024 The Science Behind EPS Floor Heating Panels: How They Work and Why They’re Effective

In recent years, the demand for efficient and eco-friendly home heating solutions has surged, leading to the development and popularity of innovative products like EPS floor heating panels.