Technology

24

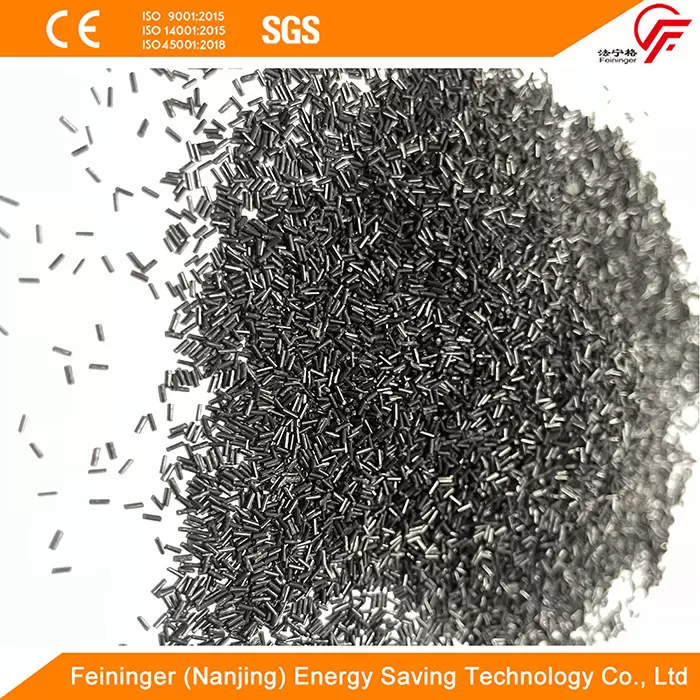

Apr . 2024In the realm of material science, Expanded Polystyrene (EPS) with graphite particles is emerging as a revolutionary solution in various industries due to its enhanced properties and versatility. CHINAFEININGER, a leader in this technology, has pioneered the integration of graphite into EPS to create a material that not only surpasses traditional EPS in performance but also offers environmental benefits. This article explores several real-world applications of EPS graphite particles, demonstrating their effectiveness and diverse utility.

EPS, or polystyrene foam, is made by adding a foaming agent to polystyrene resin and then softening it through heating, which results in a rigid foam structure composed of uniform closed cavities. This structure gives EPS its characteristic low water absorption, excellent insulation properties, and lightweight. The integration of graphite particles into EPS enhances these inherent qualities by improving compressive strength and thermal conductivity, making it an environmentally friendly option that excels in demanding applications, such as high-end helmet materials.

One of the standout applications of EPS graphite particles developed by CHINAFEININGER is in the production of high-end helmets, particularly for riders. Helmets require materials that can absorb impact effectively while remaining light and comfortable for the user. Traditional EPS helmets are effective but can lack the necessary strength and thermal regulation needed for prolonged use in varying environments.

CHINAFEININGER has utilized EPS graphite particles to create helmets that not only meet but exceed safety standards. The addition of graphite significantly enhances the material's deformability under pressure, an essential characteristic for absorbing the energy from impacts. Furthermore, the improved thermal conductivity ensures that the helmet remains more comfortable for the user, regulating temperature more effectively during use. This application has seen widespread adoption in the motorcycle and bicycling industries, where safety and comfort are paramount.

Building and construction are some of the most significant areas where EPS graphite particles have made a profound impact. Insulation materials are critical in controlling the energy costs and environmental footprint of buildings.

In both residential and commercial buildings, insulation with EPS graphite particles provided by CHINAFEININGER has proven to be more effective than traditional materials. The graphite particles enhance the insulative properties of EPS, allowing for thinner panels that provide the same or better thermal resistance as thicker ones made of standard EPS. This improvement not only reduces material costs but also decreases the energy needed for heating and cooling, a critical factor in green building certifications.

In the packaging industry, the demand for lightweight and strong materials is high. EPS graphite particles offer an ideal solution due to their improved structural integrity and insulation properties.

CHINAFEININGER has developed specialized packaging solutions for sensitive electronic devices using EPS graphite particles. These packaging materials protect against mechanical damage during transport and handling while preventing static buildup and offering excellent thermal protection. This application is particularly valuable in the shipping of electronics, which are susceptible to damage from excessive heat and handling.

EPS graphite particles are also finding their way into more specialized applications, such as components in lightweight vehicles and sports equipment.

Automotive and aerospace industries are benefiting from EPS graphite particles in manufacturing components that require a balance between lightness and strength. CHINAFEININGER has partnered with several automotive companies to develop interior components that reduce the overall weight of the vehicle, leading to better fuel efficiency and reduced emissions.

In sports, equipment like protective gear, racquets, and boots are using EPS graphite materials to reduce weight without compromising on safety or performance. These products benefit from the material’s shock-absorbing properties and its ability to withstand repeated impacts.

The diverse applications of EPS graphite particles showcase their versatility and superior performance in multiple fields. CHINAFEININGER's innovative approach in enhancing EPS with graphite particles has opened new avenues for this material, making it a preferred choice for environmentally conscious and performance-oriented applications. As industries continue to seek advanced materials that offer both functionality and environmental sustainability, EPS graphite particles stand out as a future-forward solution, promising to shape the material landscape for years to come.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

27 Jun 2024

27 Jun 2024 Choosing the Right TPU Underwater Pelletizer for Your Manufacturing Needs

In the realm of polymer processing, selecting the appropriate equipment can significantly impact efficiency, product quality, and overall operational costs. When it comes to TPU (Thermoplastic Polyurethane) underwater pelletizers, making an informed decision is crucial to meeting production goals effectively.

17 Jul 2024

17 Jul 2024 Ultimate Guide to Recycling Pelletizers: How They Work

Recycling pelletizers are an essential part of the plastic recycling industry, transforming plastic waste into reusable pellets that can be used in various manufacturing processes.

05 Mar 2025

05 Mar 2025 How PET Foam Sheet Production Lines Improve Efficiency and Reduce Waste

China Feininger, a leading manufacturer in XPS and PET foam extrusion technology, has developed high-performance PET foam sheet production lines that not only enhance manufacturing efficiency but also significantly reduce environmental impact.