Technology

17

Apr . 2024In the realm of polymer processing and manufacturing, the Micro Supercritical CO₂&N₂ Injection Machine from China Feininger has revolutionized the industry with its ability to enhance product quality across various applications. In this blog post, we will delve into the innovative features, working principles, and diverse applications of this advanced injection machine, showcasing how it elevates product quality and performance.

The Micro Supercritical CO₂&N₂ Injection Machine, developed by China Feininger, is a cutting-edge equipment designed to inject CO₂ as a blowing agent into the polymer melt during extrusion processes. Its key features and working principles include:

CO₂ as Blowing Agent: The machine utilizes CO₂ as a blowing agent, which is injected into the barrel screw by a high-pressure injection pump. This controlled injection process ensures uniform foaming and enhanced product properties.

Constant Volume Flow Rate and Pressure: During extrusion, the machine maintains constant volume flow rate and pressure of CO₂ gas, leading to consistent foaming and improved quality of the final product.

Supercritical State Formation: Through shear mixing of the screw and convection and diffusion of the gas, the polymer in the barrel reaches a supercritical state. This supercritical state enhances mixing, dispersion, and foaming efficiency.

Pressure Drop and Rapid Nucleation: As the polymer reaches the head of the supercritical CO₂ injection equipment, a pressure drop occurs, leading to rapid nucleation and foam formation. Cooling after nucleation results in the final product with desired properties.

The Micro Supercritical CO₂&N₂ Injection Machine finds extensive applications across industries, contributing to enhanced product quality and performance. Some of the key applications include:

Packaging Industry: In the packaging industry, the machine is used to produce foamed polymer materials with improved insulation, cushioning, and barrier properties. These materials are ideal for packaging fragile or sensitive products.

Construction Sector: In construction, the machine is utilized to create lightweight and durable foamed materials for insulation, soundproofing, and structural components. The enhanced properties of these materials contribute to energy efficiency and building performance.

Automotive Manufacturing: Automotive manufacturers benefit from the machine's ability to produce lightweight foamed components with excellent mechanical properties. These components contribute to fuel efficiency, vehicle safety, and overall performance.

Medical Device Production: The medical industry uses foamed polymer materials produced by the machine for various applications, including packaging, implants, and medical device components. The materials' sterilization compatibility and biocompatibility make them suitable for medical use.

Consumer Goods: In the consumer goods sector, the machine is employed to create foamed materials for furniture, appliances, sporting equipment, and recreational products. These materials offer enhanced comfort, durability, and aesthetics.

The Micro Supercritical CO₂&N₂ Injection Machine offers several advantages that contribute to enhancing product quality:

Uniform Foaming: The controlled injection of CO₂ ensures uniform foaming throughout the polymer melt, resulting in consistent product quality and properties.

Enhanced Properties: The supercritical state of the polymer leads to improved mechanical, thermal, and barrier properties, making the final product more durable and functional.

Customizable Solutions: The machine's capabilities can be customized to meet specific application requirements, allowing for tailored foaming profiles and product characteristics.

Energy Efficiency: The optimized foaming process reduces material usage and energy consumption, leading to cost savings and environmental benefits.

Quality Assurance: The machine's precise control over process parameters ensures quality assurance, minimizing defects and variations in the final product.

As the demand for high-quality, sustainable products continues to grow, the Micro Supercritical CO₂&N₂ Injection Machine is poised to drive future trends and innovations in polymer processing. Some potential developments may include:

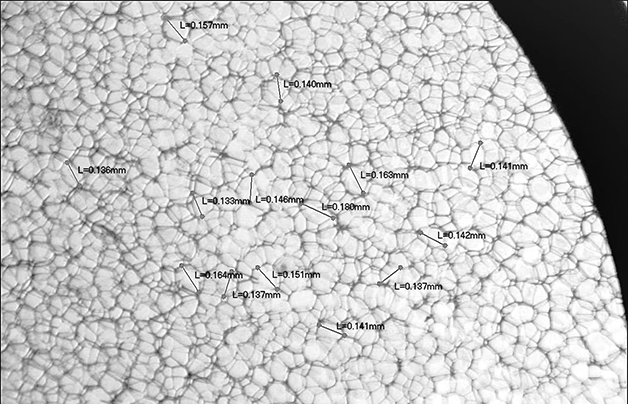

Advanced Foaming Technologies: Continued advancements in foaming technologies, such as nano-cellular foams and microcellular structures, to further enhance product properties and performance.

Integration of Smart Controls: Integration of smart sensors, automation, and data analytics for real-time monitoring and optimization of process parameters, ensuring consistent quality and efficiency.

Material Compatibility: Expansion of the machine's compatibility with a wider range of polymers, additives, and formulations to address diverse industry needs and applications.

Sustainability Focus: Emphasis on sustainability through the use of bio-based foaming agents, recycled materials, and energy-efficient processes, aligning with global sustainability goals.

The Micro Supercritical CO₂&N₂ Injection Machine from China Feininger represents a significant advancement in polymer processing technology, offering enhanced product quality, versatility, and sustainability across industries. Its ability to create uniform foaming, improve product properties, and ensure quality assurance makes it a valuable asset for manufacturers seeking innovative solutions. As industry demands evolve and sustainability becomes increasingly important, the Micro Supercritical CO₂&N₂ Injection Machine is poised to lead the way in driving product quality and performance to new heights.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

12 Jul 2023

12 Jul 2023 Advantages of feininger ETPU foamed particles

Feininger has been committed to the research of supercritical CO2 foaming equipment, using CO2 in supercritical state as a physical foaming agent applied to foam extrusion process, can produce microporous plastics with small and dense pores and improved mechanical properties, while achieving energy saving and consumption reduction. Feininger supercritical CO2 extrusion foam ETPU has the advantages of high rate and high resilience.

20 Dec 2024

20 Dec 2024 Step-by-Step Process: How a PET Foam Core Production Line Works

The production of PET (Polyethylene Terephthalate) foam core materials has seen a significant rise in popularity due to its lightweight, durable, and eco-friendly properties.

26 Feb 2024

26 Feb 2024 Feininger to Showcase Cutting-Edge XPS Technology at UzBuild - Uzbekistan International Exhibition 2024

Feininger, the pioneering manufacturer of XPS Extrusion Line and XPS Foam Board based in China, is poised to make a significant impact at the highly anticipated UzBuild - Uzbekistan International Exhibition 2024.