Technology

18

Sep . 2023Feininger, a leading Chinese extrusion equipment manufacturer, has been at the forefront of innovation in the field. In this blog, we'll delve into the fascinating world of extruders and explore the key differences between single screw and twin screw extruders. These two types of extruders play pivotal roles in various industries, from plastics and food processing to pharmaceuticals and beyond. Understanding the distinctions between them is crucial for anyone looking to optimize their manufacturing processes and achieve the best results. So, let's embark on this journey to unravel the unique characteristics and applications of single screw and twin screw extruders.

Single screw extruder: As the name implies, a single screw extruder is a cylinder with a screw inside.It is mainly used for extrusion of pipe, sheet, plate and profile, and granulation of some modified materials.Similarly, the twin screw extruder is a barrel with two screws.Compared with the single screw extruder, the twin screw extruder classification is relatively complex.It is mainly used for granulation of modified plastics, such as fiber reinforcement, flame retardant and enhanced filling, mixing and extrusion of thermosetting plastics, extrusion and granulation of hot melt adhesive and PU reaction.

The two types of equipment have their own characteristics. What are the main differences between the twin-screw extruder and the single-screw extruder?

1, Price:

The single-screw extruder has a simple structure and low price, while the twin-screw extruder has a complex structure and a high price. The price vary by manufacturer and model.

2, Operability:

There is little difference between the two in terms of operation. However, the process and formula of the single-screw extruder are relatively simple, while the process and formula of the twin-screw extruder will be more complicated, and the actual operating standards of the processing technology are relatively high.

3, Production capacity and energy consumption:

The twin-screw extruder has large output, fast extrusion speed, and low energy consumption per unit output, while the single-screw extruder is worse. The power consumption of the twin-screw extruder is about 30% lower than that of the single-screw extruder.

4, Mixing and plasticizing ability:

The single screw is suitable for plasticizing extrusion of polymers and extrusion processing of pellets. It has little shear degradation of polymers, and it can be used in a wide range of materials. The twin-screw extruder has good mixing and plasticizing ability, and is more suitable for the modification of plastics.

5, Maintenance:

The maintenance of single-screw extruder will be simpler than that of twin-screw, because the structure of single-screw is simpler and easier to repair.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

09 May 2024

09 May 2024 A Deep Dive into the Efficiency of CO2 XPS Production Lines

In the ever-evolving landscape of industrial manufacturing, the push towards more sustainable and efficient production methods has led to significant advancements in various technologies. One such innovation is the CO2 XPS production line.

05 Jun 2024

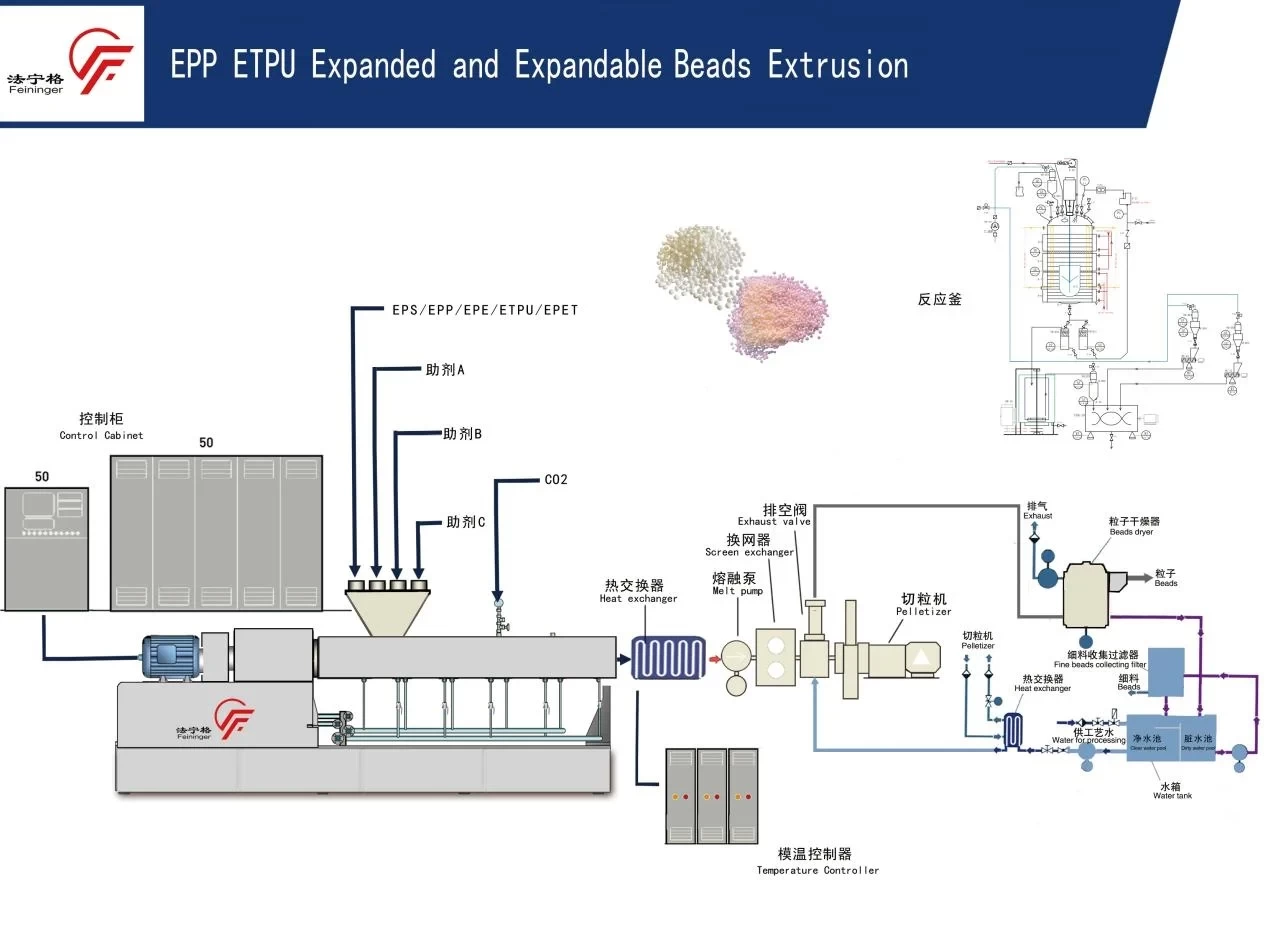

05 Jun 2024 Optimizing Your Production with Advanced EPP Particle Line Technology

In the ever-evolving landscape of manufacturing, efficiency and innovation are paramount. As industries across the globe strive to enhance production capabilities, the focus on advanced technologies such as EPP particle line technology has become more pronounced.

02 Jul 2024

02 Jul 2024 Revolutionizing Manufacturing: An Inside Look at the PET Foam Sheet Production Line

In the ever-evolving world of manufacturing, PET foam sheets have emerged as a versatile and essential material. From automotive to construction, these lightweight yet strong sheets are revolutionizing various industries.