Technology

22

Sep . 2023A cold storage is a building that uses artificial refrigeration to make a fixed space reach a specified temperature, which is convenient for storing items. We all know that the quality of the cold storage is good or bad, in addition to the refrigeration equipment, another important part is the insulation board. The purpose of the insulation board is to reduce the intrusion of external heat into the cold storage, prevent the leakage of cold air in the cold storage, and achieve better control of the temperature in the cold storage. As a thermal insulation material, thermal insulation board plays an important role in the initial investment cost and long-term benefits in the construction of the project. Cheap raw materials may reduce the initial investment, but high-quality raw materials can be exchanged for long-term energy saving. There are many choices of insulation board. Cold storage extruded plastic board is an excellent cold storage insulation material, so how to choose a suitable cold storage insulation board?

1. Thermal insulation performance

For cold storage insulation materials, our primary requirement is its thermal insulation performance. The extruded plastic board has the characteristics of high thermal resistance, low linearity and low expansion ratio. These advantages make the extruded plastic board have excellent thermal insulation performance.

2. Dimensional stability

Cold storage insulation materials should pay attention to the dimensional stability after temperature changes. After dimensional changes, it is often manifested as cracking or falling off, which will inevitably affect the normal use of the cold storage. The extruded board has sufficient foaming, and the closed cell rate is as high as 99%, so that the raw material and the foaming agent can fully react to achieve dimensional stability and ensure small deformation of the board for a long time.

3. Durability

Cold storage insulation materials should choose materials that can maintain stability for a long time. Although some inferior materials have good toughness on the surface, they will become brittle after a period of use and will no longer be impact-resistant. In the humid environment of the cold storage, the chemical properties of the extruded board are stable, which can effectively prevent the penetration of moisture, avoid the accumulation of water inside the board due to condensation, and the cracking in case of freezing and thawing, which can ensure the long-term stability of the product in all aspects.

4. Choose regular manufacturers

The first requirement of cold storage insulation materials is thermal insulation performance, and the quality of thermal insulation performance cannot be observed with the naked eye before it is actually put into use, and it is too late to observe the difference in power consumption. Therefore, we must choose insulation materials produced by regular manufacturers. Regular manufacturers can strictly control the selection of materials and production. Before leaving the factory, they have passed a large number of experimental tests to strictly control the quality.

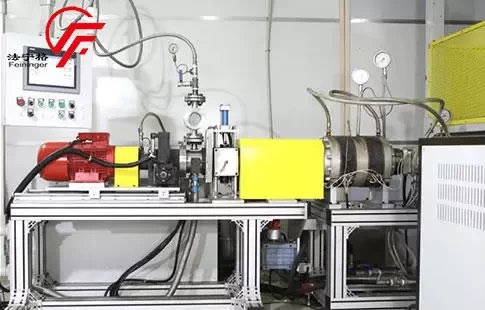

Feininger is one of the top ten enterprises in China's light industry, and it is also the drafting unit of the industry standard QB/T5166--2017 "Extruded Plastic Sheet for Cold Storage XPS".

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

13 Jun 2025

13 Jun 2025 How XPS Foam Board Production Lines Are Revolutionizing Insulation Manufacturing

In the ever-evolving world of construction materials, XPS Foam Board Production Lines are playing a transformative role in redefining how we insulate buildings.

02 Apr 2025

02 Apr 2025 ETPU Beads Foam Production Line: Key Features and Innovations for Modern Foam Manufacturing

Central to the production of ETPU foam is the ETPU Beads Foam Production Line, a sophisticated system that integrates cutting-edge technology to ensure the highest levels of performance and quality.

13 Oct 2023

13 Oct 2023 See You At The 134rd China Import and Export Fair

The China Import and Export Fair (Canton Fair), founded on April 25, 1957, is held in Guangzhou every spring and autumn, jointly sponsored by the Ministry of Commerce and the People's Government of Guangdong Province, and undertaken by China Foreign Trade Center.