Technology

15

Jul . 2025Selecting the right XPS (Extruded Polystyrene) extrusion line is critical for producing high-quality insulation boards that meet market demands and regulatory requirements. This guide outlines key factors to consider, combining technical specifications, environmental compliance, and operational efficiency to help you make an informed decision.

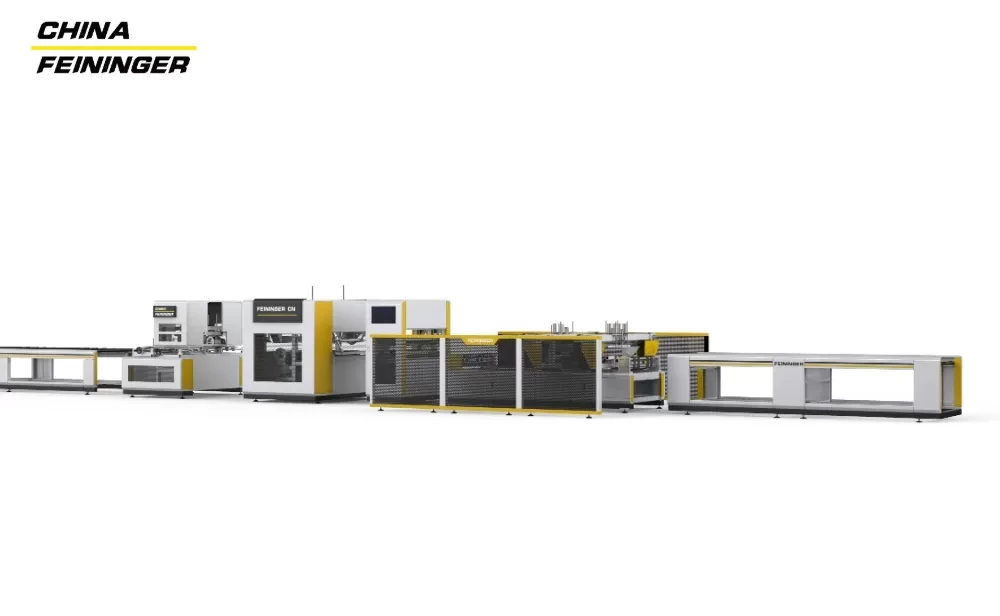

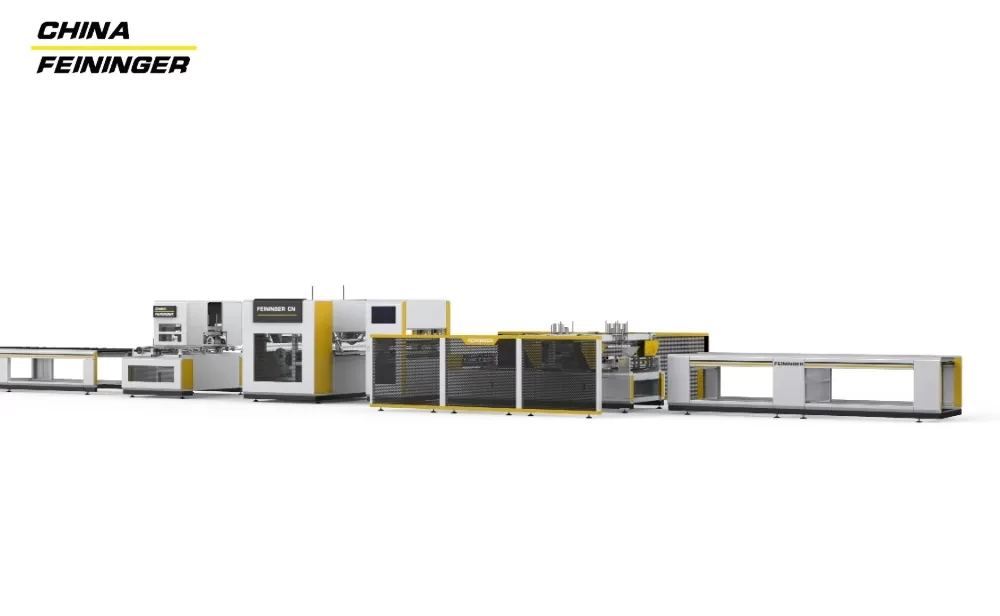

The extrusion line's technical parameters directly impact output quality and efficiency. Key considerations include:

• Output Capacity: Choose lines with adjustable production rates (e.g., 180–450 m³/24h) based on market demand. For example, Feininger FS85T/250 model can produce up to 450 m³/day, suitable for large-scale projects .

• Product Range: Ensure the line supports the required thickness (20–200mm) and width (600–1200 mm). Advanced models like those from Feininger allow customization for specific applications, such as roofing or flooring .

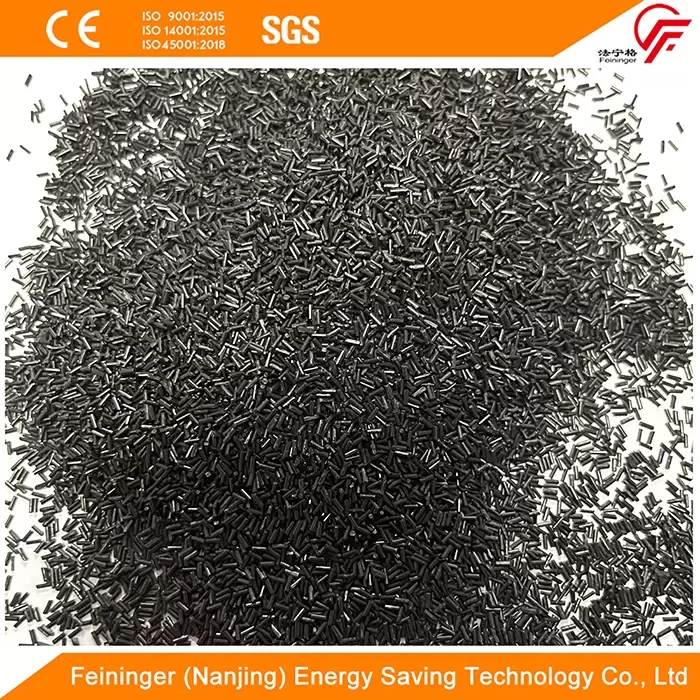

• Material Compatibility: Opt for lines that handle 100% recycled polystyrene (PS) granules, reducing waste and costs. Some systems, integrate waste recycling into the production process .

Model | Output(kg/hr) | Blowing Agents | Product width(mm) | Product Thickness(mm) | Factory Size(L*W*H) |

FS120/150 | 200-350 | CO₂+Ethanol Methanol HFC, HCFC, HFO, Butane, PropaneLPG DME,H₂O | 600 900 1200 ... | 20-60 | ≥40X10X4.5 |

FS150/200 | 350-550 | 20-100 | ≥40X10X4.5 | ||

FS75T/200 | 400-650 | 20-100 | ≥65X12X6.5 | ||

FS85T/250 | 600-850 | 30-120 | ≥70X12X6.5 | ||

FS95T/300 | 800-1200 | 40-150 | ≥80X15X8 | ||

FS110T/400 | 1000-1500 | 50-200 | ≥120X20X10 | ||

FS125T/400 | 1500-2000 | 50-200 | ≥120X20X10 | ||

FS135T/500 | 2000-3000 | 50-200 | ≥150X20X10 |

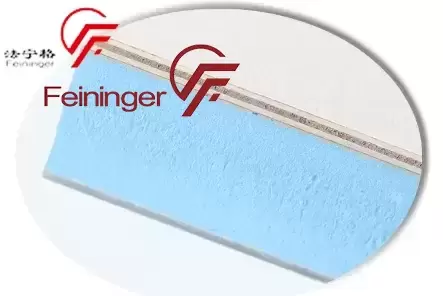

• Closed-Cell Structure: Look for lines that produce boards with uniform closed-cell honeycomb structures, ensuring low thermal conductivity (≤0.028 W/m·K) and high compressive strength (≥250 kPa) .

• Automation: Advanced systems use PLC-controlled automation for precise mixing, dosing, and cutting. Feininger’s vacuum gravity feeding system and hydraulic screen changers enhance material uniformity and reduce downtime .

• Testing Compliance: Verify compliance with standards like GB/T 30595-2024 (China) and EN 13164 (EU), which mandate strict tests for density, water absorption, and fire resistance .

• Green Foaming Technology: Adopt CO₂ or N₂-based foaming (e.g., Feininger’s supercritical CO₂ technology) to eliminate ozone-depleting substances like HFC-134a, aligning with EU’s 2025 fluorine ban .

• Emission Control: Choose lines with integrated gas waste processing system (e.g., activated carbon adsorption + catalytic combustion) to meet GB31572-2015 standards for VOCs and particulate matter .

• Recyclability: Prioritize lines that reuse production scraps and support recycled PS input, contributing to circular economy goals .

• Energy-Saving Design: Systems with waste heat recovery, variable-frequency drives (VFDs), and energy-efficient motors (e.g., 150 kW total power for Uma-XPS-135/150) reduce operational costs by 20–50% .

• Low-Carbon Certification: Opt for equipment with energy-saving certifications (e.g., China’s Green Building Label) to qualify for government incentives .

• Local Standards: Ensure the line meets regional regulations. For example, Urumqi’s environmental approvals require fabric filter and closed-loop wastewater systems .

• International Certification: For export markets, prioritize lines with CE marking compliant with EN 16516 (VOC ≤200 μg/m³) and EN 13501-1 (fire safety) .

• Track Record: Evaluate suppliers like Feininger , which have proven expertise in CO₂ foaming and modular design .

• Technical Support: Choose suppliers offering installation, operator training, and 24/7 maintenance to minimize downtime.

• Total Cost of Ownership (TCO): Balance upfront investment with long-term savings from energy efficiency and reduced waste. For instance, CO₂-foamed lines may cost more initially but save on raw materials and compliance .

• Government Incentives: Explore subsidies for energy-efficient equipment or recycled material use, as highlighted in energy-saving assessments .

Selecting an XPS extrusion line requires a holistic approach, balancing technical excellence, environmental responsibility, and economic viability. Prioritize lines with CO₂foaming technology, automated controls, and compliance with GB/T 30595-2024 and EU standards. Partner with reputable suppliers like Feininger to access cutting-edge solutions tailored to your production scale and market demands. By aligning with global sustainability trends and local regulations, your investment will yield high-quality products that thrive in both domestic and international markets.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

18 Sep 2024

18 Sep 2024 Maximizing Thermal Performance with EPS Graphite Particle Technology

In today's fast-paced world, effective thermal management is crucial for a wide range of applications, from construction to electronics. One of the most innovative solutions making waves in the industry is the use of EPS (Expanded Polystyrene) Graphite Particle technology.

01 Sep 2023

01 Sep 2023 Durability and Versatility of Wooden Layer Sandwich Boards

Welcome to the world of wooden layer sandwich boards! These innovative and versatile building materials have been gaining popularity for their durability, strength, and aesthetic appeal.

13 Jun 2024

13 Jun 2024 Unveiling the Advantages of XPS with PVC Sandwich Panels in Construction

Are you looking for a game-changing solution to revolutionize your construction projects? Look no further than XPS with PVC sandwich panels. These innovative panels are making waves in the industry, offering a host of benefits that can enhance both the efficiency and sustainability of your building endeavors.