Technology

19

Jun . 2024In the world of insulation materials, the choices can seem endless. Among these, XPS (Extruded Polystyrene) foam board with aluminum foil has become a significant player, particularly in scenarios requiring robust thermal resistance and moisture protection. But how does it compare to other popular insulation materials? Let's delve into a detailed comparison, highlighting the unique offerings by Feininger, a leader in the field.

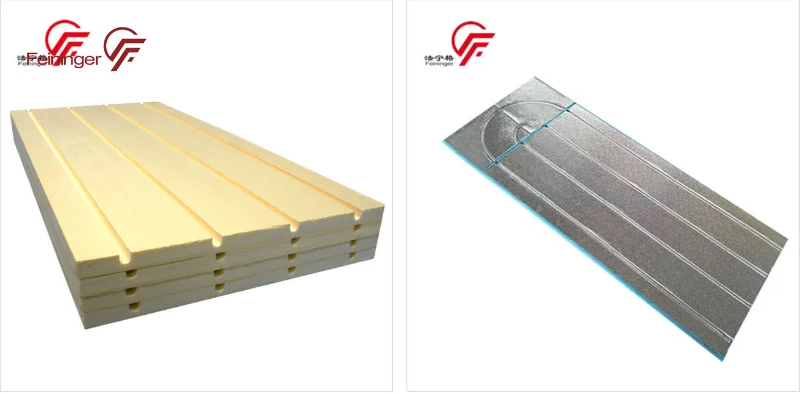

XPS foam board is renowned for its exceptional insulation properties, durability, and strength. When coupled with aluminum foil, these boards provide an enhanced barrier against heat flow and moisture, making them ideal for a variety of applications, including underfloor heating and building insulation. The aluminum layer acts as a radiant barrier, reflecting heat back into the space or away from it, thereby improving energy efficiency.

Feininger is a company that has carved a niche in the development, manufacturing, and sales of XPS foam materials and equipment. With a focus on high-quality products, such as their flagship XPS Foam Board, XPS Foam Board with Aluminum Foil, and specialized Underfloor Heating Grooved Insulation Board, Feininger stands out in the insulation industry. Their commitment to innovation is evident in their continual improvement of product features and performance, meeting the evolving needs of modern construction.

Fiberglass: Commonly used due to its affordability, fiberglass insulation has a lower R-value per inch compared to XPS foam board with aluminum foil. While fiberglass is effective, it can settle over time and absorb moisture, which potentially reduces its insulative effectiveness.

Cellulose: This eco-friendly option is made from recycled paper products. It is usually cheaper than XPS but is more susceptible to moisture, which can compromise its structural integrity and thermal resistance.

Spray Foam: Offering high R-values and air sealing properties, spray foam is a potent insulator. However, it is more expensive and must be professionally installed, unlike XPS foam boards which can be handled and installed more easily.

Polyisocyanurate (Polyiso): Known for its high thermal resistance, polyiso is often used in roof and wall applications. While it has higher initial R-values, these can decrease over time, unlike the stable R-value of XPS foam boards.

Opting for Feininger’s XPS Foam Board with Aluminum Foil offers several advantages:

Higher R-value: It provides superior insulation per inch of thickness, ensuring better energy conservation in buildings.

Moisture Resistance: The inherent properties of XPS combined with the reflective qualities of aluminum foil create a moisture-resistant barrier that is ideal for humid or wet climates.When comparing insulation materials, it’s clear that XPS foam board with aluminum foil stands out for its efficiency and durability. Feininger’s dedication to quality and innovation makes their products a top choice for professionals and homeowners alike. Whether you’re building a new home, upgrading your insulation, or installing specialized heating solutions, Feininger’s range of products offers reliable, high-performance options that cater to diverse needs.

For more information on Feininger and their products, consider contacting them directly or visiting their website to learn more about how their insulation solutions can benefit your next project.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

16 Apr 2025

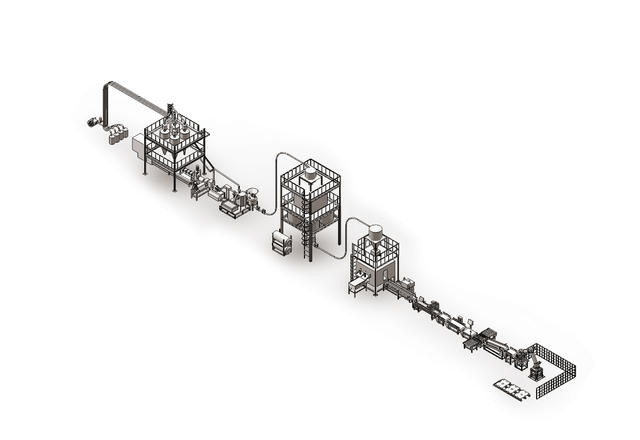

16 Apr 2025 Streamlining Production with Feininger's EPS Beads Foam Extrusion Line

In the world of foam production, precision and consistency are key to achieving high-quality products. Whether it's for packaging, insulation, or construction applications, Expanded Polystyrene (EPS) foam plays a crucial role in numerous industries.

07 Mar 2024

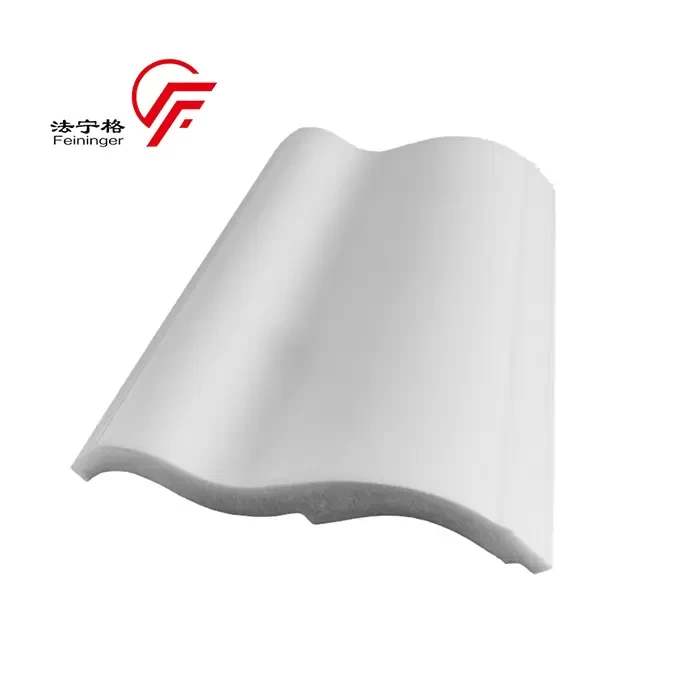

07 Mar 2024 XPS Decorative Moulding: Enhance Interiors with Style

Are you seeking to elevate your space with a touch of elegance and sophistication? Look no further than XPS decorative moulding. Transforming ordinary rooms into extraordinary spaces, XPS decorative moulding offers a seamless way to add charm and character to your home or office.

15 Aug 2025

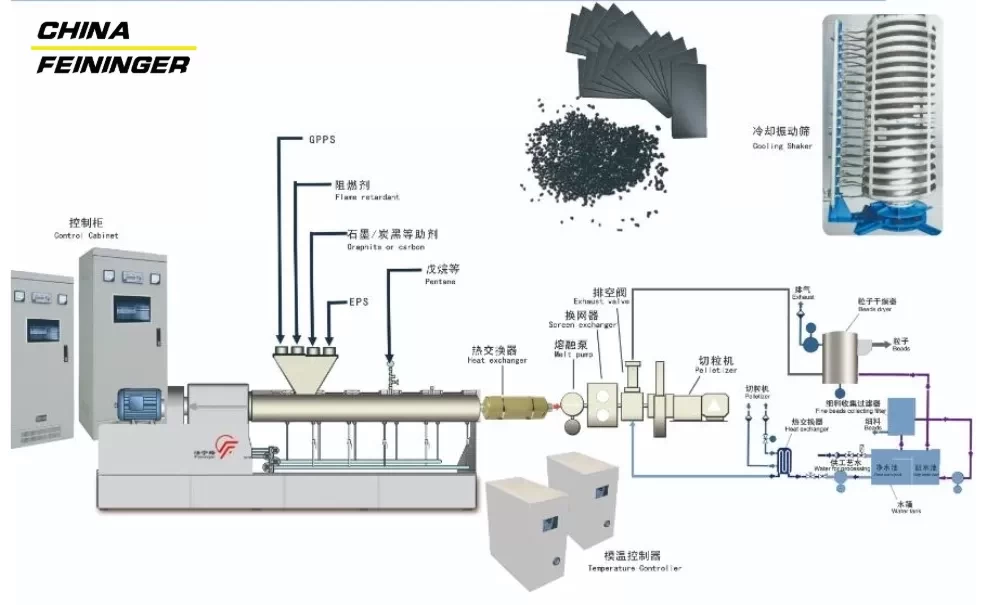

15 Aug 2025 Process Flow for Producing Graphite EPS by Extrusion Method

Process Flow for Producing Graphite EPS by Extrusion Method