Technology

13

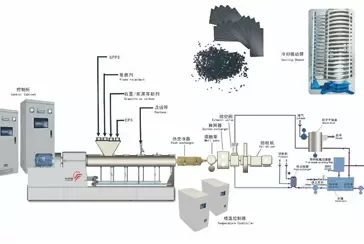

Jun . 2025In the ever-evolving world of construction materials, XPS Foam Board Production Lines are playing a transformative role in redefining how we insulate buildings. As demands for energy-efficient, sustainable, and cost-effective solutions rise, manufacturers are turning to cutting-edge production systems to meet the challenge—and leading the charge is China Feininger, a pioneer in both the production of XPS foam boards and the manufacturing of production equipment.

Extruded Polystyrene (XPS) foam board is a closed-cell insulation material known for its outstanding thermal performance, high compressive strength, and moisture resistance. Commonly used in roofing, wall insulation, and under-slab applications, XPS foam boards are essential to achieving modern energy efficiency standards in residential and commercial buildings.

The performance of an XPS foam board is only as good as the production line behind it. Traditional manufacturing techniques often struggle to balance quality, output, and environmental impact. However, Feininger's advanced XPS Foam Board Production Line changes that equation.

High Output, Low Energy Use

Feininger’s production lines are engineered for maximum efficiency, delivering high-capacity output with low energy consumption. The result? Lower operational costs and a faster return on investment for manufacturers.

Scientifically Designed Transmission System

The spiral screw structure ensures even mixing of raw materials without dead angles, resulting in consistent foam quality. The high-torque gear transmission reduces power use while maintaining operational stability.

Cleaner Production Environment

The automatic feeding system keeps raw materials enclosed, minimizing waste and maintaining a clean workshop—an essential requirement for today’s environmentally conscious operations.

Full-Area Cooling Technology

Proprietary cooling design ensures uniform temperature control, allowing for more consistent cell structure and higher product quality.

What truly sets Feininger apart is its adoption of CO₂ as a blowing agent—a breakthrough that significantly enhances both environmental performance and product quality. Unlike traditional chemical foaming agents, CO₂ is non-toxic, non-flammable, and compliant with stringent global emission standards.

This technology offers several clear benefits:

✅ Eco-Friendly Manufacturing: CO₂ foaming dramatically reduces the release of ozone-depleting substances.

✅ Superior Cell Structure: Optimized control over foam density and strength.

✅ Enhanced Insulation Performance: Resulting boards offer better thermal resistance with reduced material weight.

As China’s first professional manufacturer of both XPS foam board and its associated production line equipment, Feininger has decades of expertise and innovation behind every solution. More than just machines, Feininger offers:

✅ Free technical support for setup and production optimization.

✅ Custom solutions for global clients, from small factories to industrial-scale producers.

✅ Proven success in both domestic and international markets.

In the push for smarter, greener construction, XPS Foam Board Production Lines are more than just equipment—they’re the foundation of future-ready building materials. Feininger’s commitment to sustainability, performance, and innovation makes it a global leader in this field.

Whether you’re an insulation manufacturer looking to expand your capabilities or a new investor exploring opportunities in green building materials, partnering with Feininger could be your next strategic step.

Explore Feininger’s full line of XPS Foam Board Production solutions and experience the future of insulation manufacturing today.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

24 Jan 2024

24 Jan 2024 Streamline Your Cornice Production with the XPS Cornice Production Line

Are you tired of the traditional and time-consuming methods of cornice production? Do you dream of streamlining your process, increasing efficiency, and boosting productivity? Well, we have some exciting news for you!

11 Apr 2025

11 Apr 2025 Advanced Technology in EPS Beads Foam Production: A Look at Feininger’s Cutting-Edge Solutions

In the world of foam production, particularly EPS (Expanded Polystyrene), technology plays a crucial role in determining product quality, operational efficiency, and overall cost-effectiveness.

05 Nov 2024

05 Nov 2024 From Lab to Industry: Applications of the Beads Foam Experiment Machine

In the world of material science and manufacturing, innovation is driven by advanced research and testing technologies. One such technological marvel is the Beads Foam Experiment Machine, particularly designed for testing thermoplastic materials like PBAT, PA, and PET.