Technology

06

Jun . 2025In today's highly competitive building materials industry, efficiency and sustainability are more important than ever. For manufacturers looking to improve both product quality and production efficiency, customizing your PS Skirting Production Line is a key strategy. At Feininger, we specialize in advanced skirting line technology that goes beyond traditional methods—introducing supercritical CO₂ physical foaming to create lightweight, eco-friendly PS products with superior performance.

Unlike traditional chemical foaming, Feininger's production lines use supercritical carbon dioxide (CO₂) as a physical foaming agent. This method offers multiple advantages:

Environmentally friendly: No toxic chemical residues.

Lower product density: Reduces raw material usage and product weight.

Better dimensional stability: Ensures consistent quality and surface smoothness.

This innovation allows manufacturers to produce high-quality PS skirting boards with improved sustainability, cost-efficiency, and processing control.

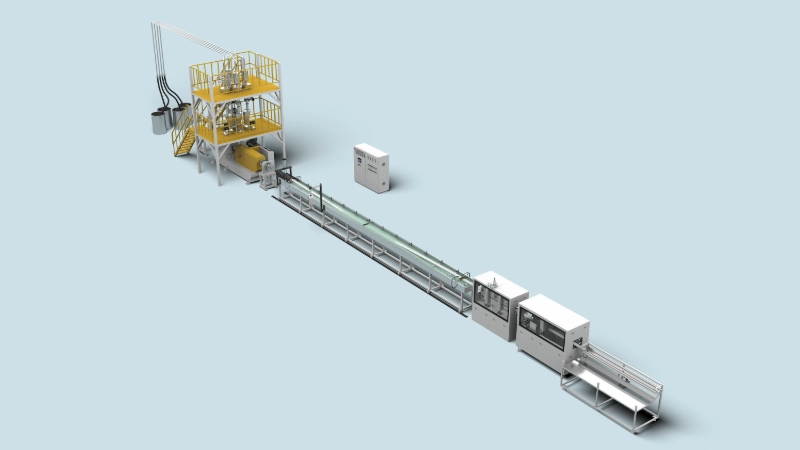

Feininger's PS skirting production line is a fully automated, high-precision system that ensures consistent product quality from start to finish. Below is a breakdown of the core steps involved:

Raw materials—typically polystyrene pellets and performance enhancers—are mixed in precise proportions and loaded into a mixer for homogeneous blending.

The blended materials are transferred via a quantitative feeder to the main extruder. The feeder adjusts flow according to the customer’s set parameters, ensuring stable output.

Inside the main extruder, the material is melted and uniformly heated. At the foaming stage, supercritical CO₂ is injected, triggering controlled physical foaming to expand the material structure.

The foamed material passes through a custom-designed mold, forming the base profile. It is then cooled and stabilized using a two-stage shaping jacket to lock in dimensions.

Further cooling takes place in a water channel, solidifying the profile and preparing it for cutting.

A high-speed tractor draws the material forward to a length-specific cutting system, ensuring all pieces meet exact product specifications.

The finished PS skirting boards are inspected, bundled, and packaged—ready for market delivery.

Every manufacturer has unique production needs. That’s why Feininger offers customization options across several stages of the PS skirting line:

Mold design: Tailored to your desired profile dimensions, shape, and surface finish.

CO₂ injection control: Adjustable foaming parameters for optimal density and expansion.

Temperature control systems: Improve foaming precision and surface quality.

Automation levels: Choose between semi-automated and fully automated lines depending on your budget and capacity requirements.

Energy-saving upgrades: Reduce power consumption through optimized motor drives and temperature sensors.

With their lightweight, waterproof, and decorative properties, PS skirting boards are widely used in:

Residential and commercial interiors

Decorative trims and molding

Renovation and prefab construction projects

Customized production lines allow you to meet varying customer demands, whether it’s classic white trims, wood-like finishes, or minimalist profiles.

With over two decades of experience in extrusion foam technology, Feininger is a trusted name in PS skirting production. Our R&D-driven solutions empower clients with:

Advanced engineering tailored to your factory needs

Sustainable technologies like supercritical CO₂ foaming

Reliable after-sales support and training

Our PS Skirting Production Lines are already serving clients across Asia, Europe, and the Americas, helping them scale production while cutting waste and energy consumption.

Investing in a customized PS Skirting Production Line is not just about upgrading equipment—it’s about improving your competitiveness, product quality, and environmental footprint. With Feininger’s advanced technology and flexible customization services, you can build a smarter, cleaner, and more efficient production future.

Ready to upgrade your skirting line? Contact Feininger today to explore your customized solution.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

07 Aug 2024

07 Aug 2024 Enhancing Efficiency: The Latest Innovations in PET Foam Core Production

The demand for lightweight, durable, and versatile materials has grown significantly in industries such as aerospace, automotive, and construction. PET foam cores have emerged as a popular choice due to their excellent mechanical properties and sustainability.

05 Jul 2024

05 Jul 2024 The Step-by-Step Process of PET Foam Sheet Production

The production of PET foam sheets is a sophisticated process that involves advanced technology and precision engineering. PET foam sheets, known for their lightweight, durable, and versatile nature, are used in various industries, including automotive, construction, and packaging.

12 Jul 2023

12 Jul 2023 Application in Cold Storage

Cold room is important facility in frozen food processing, storage and circulation. As a hich energy buildting, cold room has been concered due to hicth ooweronsumption "The Twelfth Five ear Plan"(2011-2015) raised that the energy consumption per unit of GDP should reduce 16% than the consumption ....