Technology

08

Dec . 2023There are a variety of thermal insulation products in the building thermal insulation material market, and extruded plastic boards are favored by consumers because of their health and environmental protection and excellent physical and chemical properties. At present, there are many manufacturers on the market, and the products are mixed, and it is difficult for ordinary people to distinguish them. When choosing extruded plastic boards, choosing a good manufacturer can provide more guarantees. In the face of various extruded board manufacturers on the market, how should we choose? It can be measured from the following points.

1. The production scale of the manufacturer

Formal and large-scale manufacturers can have a perfect production and management environment. Production standards determine product quality. If you want to have extruded boards with excellent performance, there are strict management from raw materials to production lines, including post-production quality inspections. Feininger has been rated as one of the top ten extruded board enterprises in China by the Ministry of Light Industry of China for many years. At present, it has opened branches in Gansu, Shenyang and Guangzhou. Before purchasing, you are welcome to visit the factory.

2. Advanced production equipment

The huge market promotes the continuous development of the industry, and consumers have higher and higher requirements for the quantity and quality of decoration building materials. Only by continuous innovation in technology and continuous updating of equipment can we be invincible in the competition. Feininger has a technology research and development center and has close cooperation with many universities and research institutes. It has been committed to the research and development of extruded thermal insulation board technology, and has continuously improved, upgraded and innovated products.

3. Manufacturer's industry reputation

A good extruded board manufacturer depends not only on the technical advantages in production, but also on whether it has a good reputation in the industry. Taking these details into consideration can avoid unnecessary troubles. If it has a very good reputation in the entire industry and is highly recognized by the public, then this is a good manufacturer. Feininger's extruded sheets have diversified specifications and excellent physical properties, which have been unanimously recognized and widely praised by users. The company's products have been exported to more than 50 countries at home and abroad.

4. Perfect after-sales system

Only manufacturers with good after-sales service are the real safe choices. Although the extruded board will not have too many after-sales problems, only by guaranteeing this insurance can the safety of the material be guaranteed during use. Feininger has passed ISO9001:2015, ISO14001:2015, ISO45001:2018 and the strict FM certification of the American Factory Association of Underwriters' Fire Standard and CE EU product standard certification. Perfect management ensures product quality. Feininger perfects the service management system while providing customers with high-quality products.

Professional skill creates quality,service makes the future.Today, I made a brief introduction to Feininger, hoping to help you choose extruded board manufacturers in the future. We also welcome people from all walks of life to visit Feininger (Nanjing) Energy Saving Technology Co.,ltd. for inspection and exchange, and look forward to cooperating with you.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

06 Jun 2025

06 Jun 2025 Customizing Your PS Skirting Production Line for Better Performance

In today's highly competitive building materials industry, efficiency and sustainability are more important than ever. For manufacturers looking to improve both product quality and production efficiency, customizing your PS Skirting Production Line is a key strategy.

16 Aug 2023

16 Aug 2023 Difference Between Physical Foaming and Chemical Foaming

Foam, with its unique structure and versatile properties, can be crafted using various methodologies, primarily bifurcated into two dominant techniques: physical and chemical foaming. Though both aim to introduce air bubbles or pockets into materials, the mechanisms and intricacies behind each process are markedly different.

12 Jul 2023

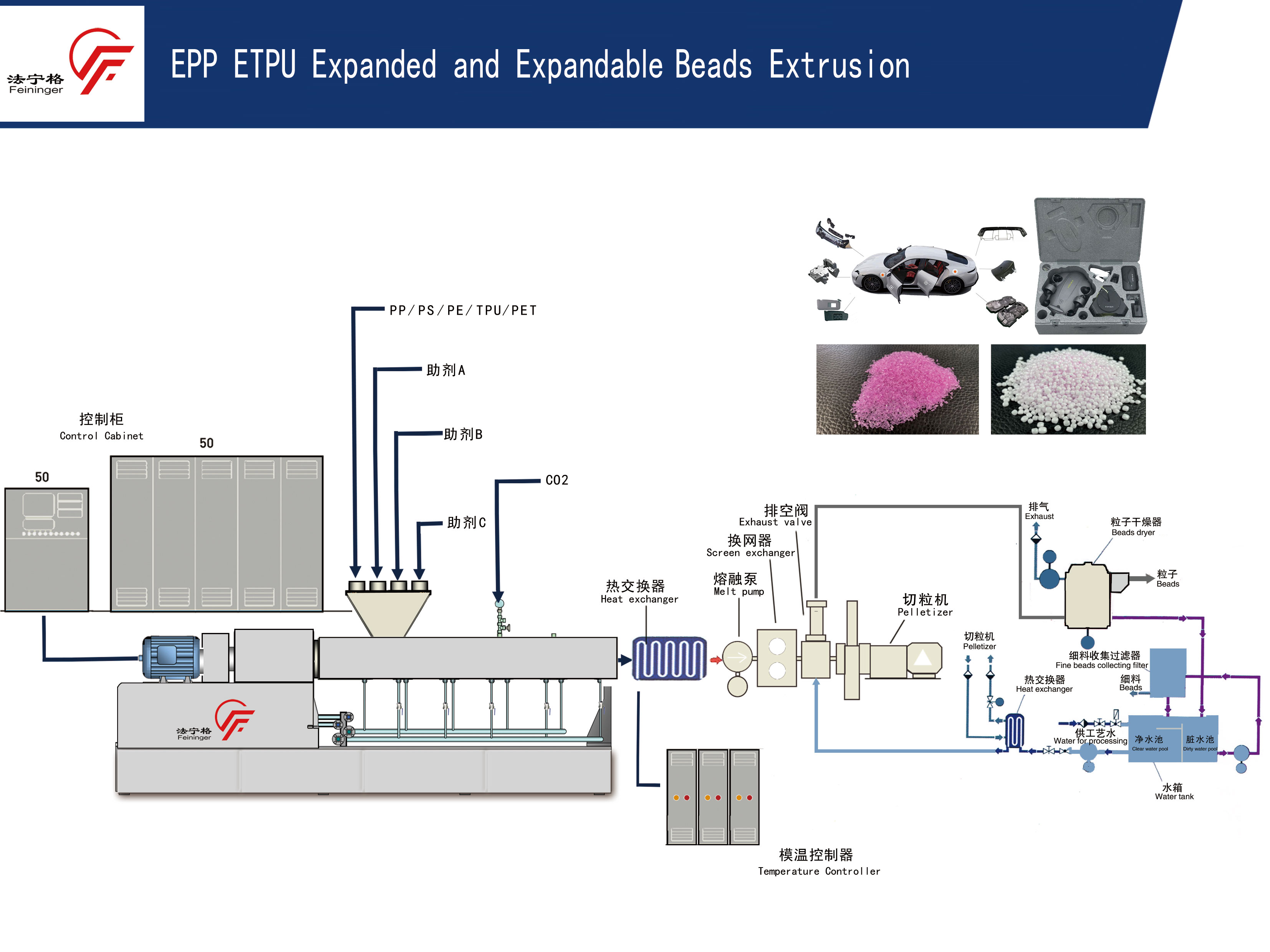

12 Jul 2023 Feininger successfully developed a one-step process for the production of epp foam beads

Jiangsu Polymer Physics Foam Engineering Technology Center has successfully developed an innovative process that can economically and efficiently extrude polypropylene (EPP) foam beads using supercritical CO2.