Technology

24

Jul . 2025In the competitive world of foam manufacturing, companies are constantly seeking solutions that enhance efficiency, product quality, and cost control. That's where Feininger's Graphite EPS Beads Foam Extrusion Line comes in — a high-tech, durable, and customizable system built on years of industry expertise and technological innovation.

Feininger’s newly developed graphite EPS production line leverages a scientific extruder design tailored specifically for expanded polystyrene beads. This system features an advanced parallel twin-screw extrusion structure that improves mixing and stability throughout the process.

Key to this innovation is the use of a uniform-temperature heat exchanger, which prevents blockages in the discharge holes and ensures that each EPS bead maintains consistent quality — a critical factor in downstream molding applications such as insulation, packaging, and lightweight construction.

Thermoplastic EPS foam beads are extruded underwater, which presents a unique challenge in managing water pressure and temperature. Feininger solves this through a scientific water system design, providing stable pressure and heat levels that eliminate blockages and minimize foam build-up inside the pipeline.

Post-extrusion, the beads are subjected to centrifugal drying and vibration cooling, using a bottom-up vibration design. This ensures the particles cool evenly, retain their shape, and are ready for storage or further processing.

Feininger understands that no two production facilities are alike. That’s why each EPS extrusion line is modular and customizable, allowing clients to fine-tune everything from output capacity to layout configurations.

Durable, low-energy extruders

Flexible design for a variety of EPS applications

High-quality output with minimal maintenance requirements

Feininger isn’t just a manufacturer — it’s a strategic partner. With rich experience in graphite EPS production, Feininger provides free technical training and ongoing support to help clients hit the ground running. No need for lengthy setup times or excessive debugging — just efficient production from day one.

Feininger’s EPS Beads Foam Extrusion Line is the smart investment for manufacturers looking to optimize productivity, reduce downtime, and meet growing market demands for premium foam products.

Explore the full product details

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

16 Nov 2023

16 Nov 2023 Let's Get To Know Feininger

Feininger is the first professional manufacturer of XPS Extrusion Line and XPS Foam Board here in China. At the same time we are the unique enterprise specializing in XPS Foam as well as developing, manufacturing and selling of XPS equipment.

24 Jul 2024

24 Jul 2024 Choosing the Right TPU Underwater Pelletizer: Key Considerations and Tips

Thermoplastic polyurethane (TPU) underwater pelletizers are essential in the polymer processing industry, especially for producing high-quality TPU pellets.

19 Jun 2024

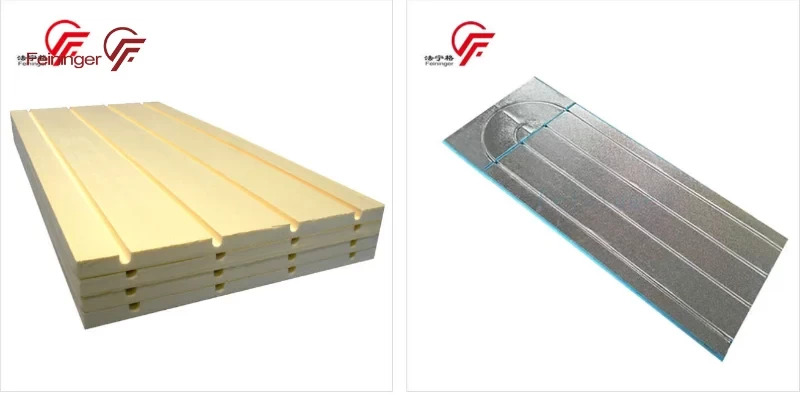

19 Jun 2024 Comparing Insulation Materials: Where Does XPS Foam Board with Aluminum Foil Stand?

In the world of insulation materials, the choices can seem endless. Among these, XPS (Extruded Polystyrene) foam board with aluminum foil has become a significant player, particularly in scenarios requiring robust thermal resistance and moisture protection.