Technology

25

Jul . 2025If you're planning to upgrade or start a new foam production facility, choosing the right extrusion line is crucial. The EPS Beads Foam Extrusion Line from Feininger delivers a compelling blend of reliability, customization, and advanced technology — making it an ideal solution for high-performance foam production.

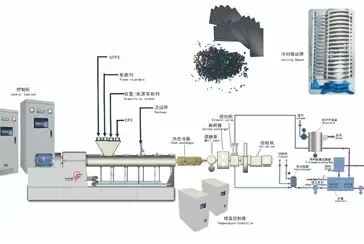

At the heart of Feininger’s line is its parallel twin-screw extruder, engineered with efficiency and precision in mind. This design improves material consistency and disperses heat uniformly — critical for producing high-quality graphite EPS beads without clogging or fluctuations.

The specially designed heat exchanger keeps the extrusion process smooth and stable, preventing issues like nozzle blockage and inconsistent foam density, which are common in less advanced systems.

EPS foam particles are formed under high water pressure, requiring a system that can withstand thermal and mechanical stress. Feininger’s extrusion line is equipped with a scientific water pressure and temperature control system, ensuring that foam exits the extruder smoothly and evenly.

Once formed, the EPS beads pass through a centrifugal dryer and a vibration cooling unit with bottom-up design — an intelligent configuration that promotes even cooling and maintains the spherical shape of each bead.

One of Feininger’s strengths lies in its modular production line architecture, allowing customers to customize their system to fit specific needs:

Output capacities for different production scales

Custom mold designs and particle sizes

Options for energy-efficient upgrades

Space-saving layouts for compact production environments

Whether you're producing EPS for insulated packaging, lightweight panels, or construction-grade insulation, Feininger ensures your system is fully aligned with your application.

Feininger believes that great equipment is only half the story. That’s why every client receives:

Free technical training

On-site installation and commissioning

Troubleshooting support and upgrade consulting

Long-term service commitment

This end-to-end service means less downtime, faster ROI, and long-term operational confidence.

With a combination of advanced extrusion design, modular customization, and expert support, Feininger’s EPS Beads Foam Extrusion Line delivers exactly what modern manufacturers need: reliability, flexibility, and high-quality results.

Ready to upgrade your EPS foam production?

Visit the product page to learn more.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

01 Dec 2023

01 Dec 2023 Maximizing Efficiency: The Advantages of EPS Beads Foam Extrusion Line

Are you in the manufacturing industry and looking for ways to boost efficiency while saving on costs? Look no further than the revolutionary EPS Beads Foam Extrusion Line.

07 Oct 2023

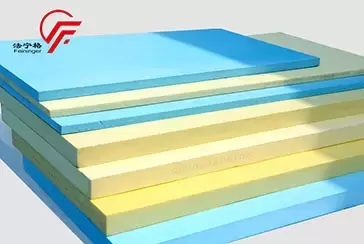

07 Oct 2023 Mastering XPS Foam Board Production: A Comprehensive Guide

Welcome to the world of XPS Foam Board production! If you're looking to delve into this fascinating field or simply want to expand your knowledge, you've come to the right place. In this comprehensive guide, we will take you on a journey through the ins and outs of mastering XPS Foam Board production.

02 Jul 2025

02 Jul 2025 Container Shipment of Cement-Coated XPS Tile Backer Board

When it comes to exporting construction materials internationally, proper packaging and container loading are just as important as the product itself. For XPS Tile Backer Boards with a cement coating, this is especially true—both to preserve product integrity and to ensure a smooth delivery process.