Technology

24 Oct 2025

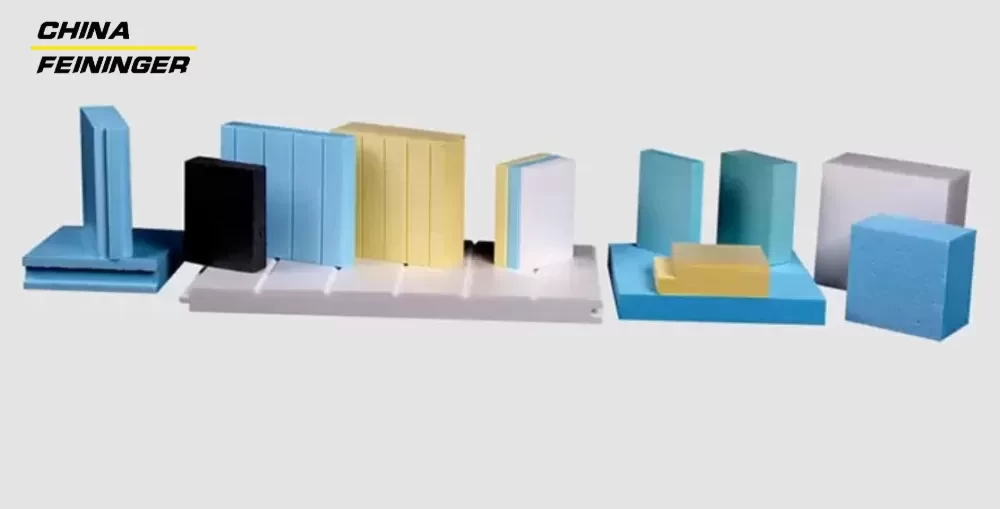

24 Oct 2025 Feininger XPS Backer Board: The Professional’s Choice for Superior Building Performance

27 Aug 2025

27 Aug 2025 Advantages of Feininger Extrusion Production Equipment for Graphite EPS Particles

Outstanding production efficiency and stability High degree of automation Product quality Energy consumption and cost advantages Strong operation and adaptability

27 Aug 2025

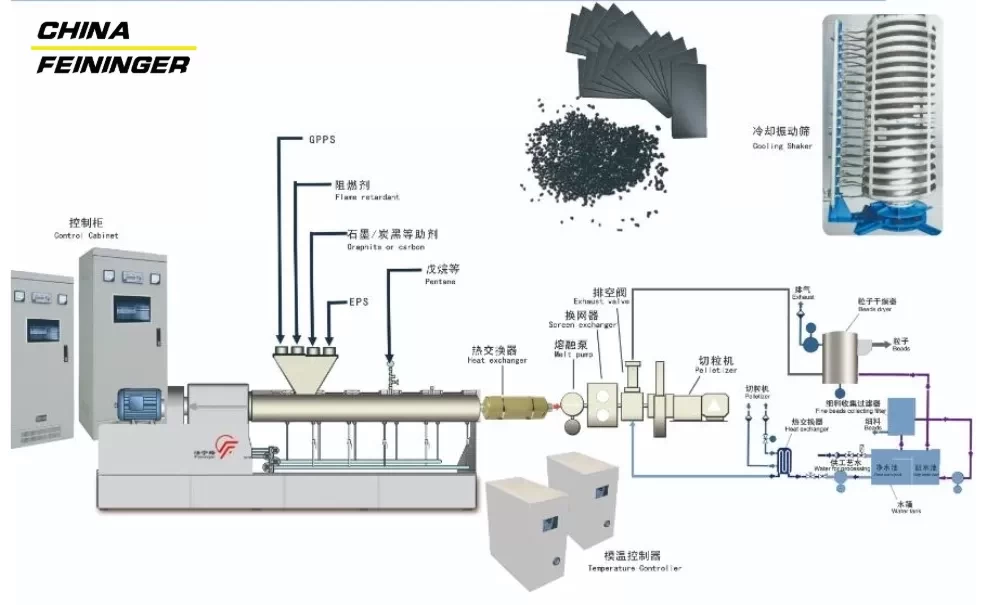

27 Aug 2025 Process Flow for Producing Graphite EPS by Extrusion Method

The process flow of producing graphite EPS (expandable polystyrene) by extrusion is to melt and mix polystyrene-based raw materials through extrusion equipment, then cut into the required particles through high-pressure underwater pelletizing, and finally carry out sieving, coating and packaging to obtain products.

25 Jul 2025

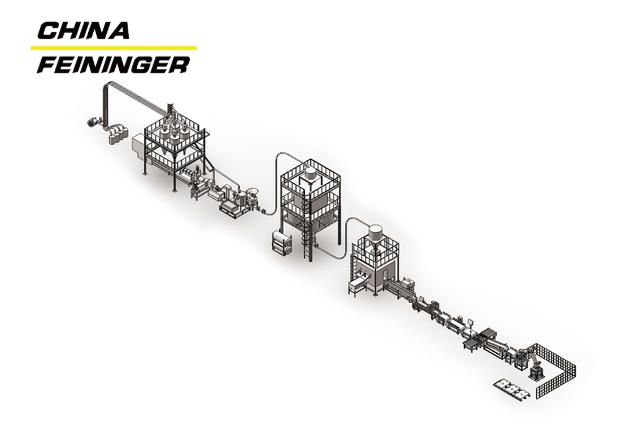

25 Jul 2025 Why Choose EPS Beads Foam Extrusion Line for Foam Production Upgrade?

The EPS Beads Foam Extrusion Line from Feininger delivers a compelling blend of reliability, customization, and advanced technology — making it an ideal solution for high-performance foam production.

24 Jul 2025

24 Jul 2025 Boosting EPS Foam Production Efficiency with Feininger’s Graphite EPS Beads Extrusion Line

That's where Feininger's Graphite EPS Beads Foam Extrusion Line comes in — a high-tech, durable, and customizable system built on years of industry expertise and technological innovation.

18 Jul 2025

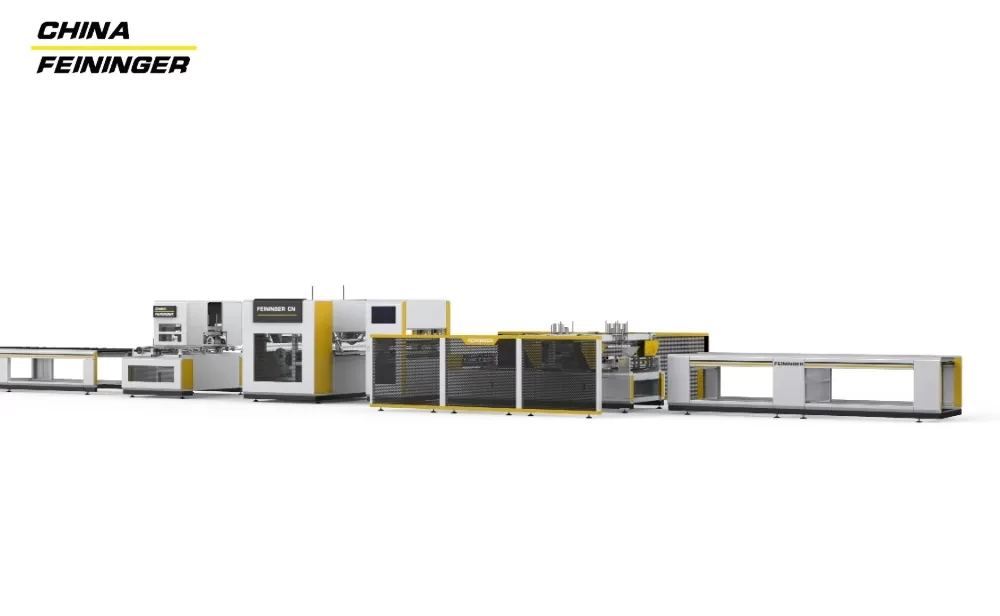

18 Jul 2025 Discover the Feininger XPS Board Production Line: A Turnkey Solution Beyond Equipment

Are you planning to launch an XPS board project but worried the production line might not meet your order volume?